Precision and Efficiency: The Role of CNC Milling in Modern Manufacturing

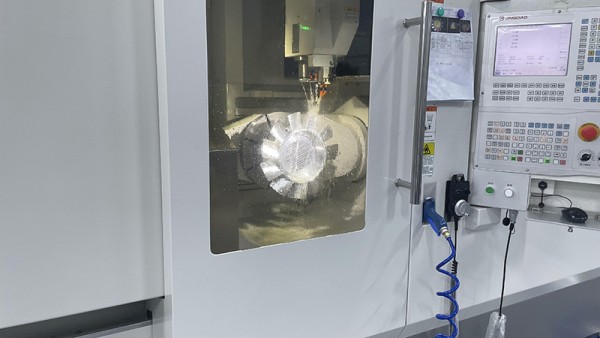

In the realm of modern manufacturing, precision and efficiency are not just desirable attributes—they are essential. As industries evolve and consumer demands for high-quality products increase, the role of CNC milling services has become increasingly significant. CNC, which stands for Computer Numerical Control, milling is a subtractive manufacturing process that uses computerized controls and rotating multi-point cutting tools to progressively remove material from a workpiece and produce a custom-designed part or product. This advanced manufacturing technique stands at the forefront of production, driving innovation and ensuring that the manufacturing industry can meet the exacting standards of today’s market.

The importance of CNC milling services in the manufacturing industry cannot be overstated. One of the primary benefits of CNC milling is its ability to produce complex shapes with high precision. Unlike manual milling, which relies on the skill and experience of the operator, CNC milling is controlled by a computer, which can execute complex cuts with a level of accuracy that is virtually unmatched. This precision is crucial in industries such as aerospace, automotive, and medical devices, where even the slightest deviation from the specified dimensions can lead to product failure or safety issues.

Moreover, CNC milling enhances efficiency in several ways. The automation of the milling process reduces the likelihood of human error, which not only improves the quality of the final product but also speeds up production times. Once a design has been programmed into the CNC machine, it can produce the same part consistently and continuously without deviation, allowing for rapid production of large quantities of components with identical specifications. This consistency is vital for manufacturers who need to maintain a high level of quality control across large production runs.

Another advantage of CNC milling services is their flexibility. The software that controls CNC machines can be updated to produce different parts, which allows manufacturers to quickly adapt to new designs or changes in product specifications. This adaptability is particularly important in a market where product life cycles are becoming shorter and the ability to bring new products to market quickly can provide a competitive edge.

CNC milling also contributes to cost savings in

Customization Capabilities: How CNC Milling Services Enhance Product Design

In the dynamic world of manufacturing, the quest for precision, efficiency, and customization is relentless. CNC milling services stand at the forefront of this pursuit, offering unparalleled capabilities that significantly enhance product design. The importance of these services in the manufacturing industry cannot be overstated, as they provide the flexibility and accuracy necessary to meet the ever-evolving demands of consumers and markets.

CNC milling, or Computer Numerical Control milling, is a subtractive manufacturing process that uses computerized controls and rotating multi-point cutting tools to progressively remove material from a workpiece and produce a custom-designed part or product. This advanced technology has revolutionized the way manufacturers approach production, allowing for the creation of complex shapes and high-precision parts with finishes that are often ready for use without additional processing.

One of the most significant advantages of CNC milling services is their customization capabilities. The precision of CNC machines enables manufacturers to produce parts with intricate details and complex geometries that would be nearly impossible to achieve with manual machining. This level of customization is crucial for industries such as aerospace, automotive, and healthcare, where the performance and reliability of components can be a matter of life and death. By utilizing CNC milling, manufacturers can tailor products to specific applications, ensuring optimal functionality and fit.

Moreover, the versatility of CNC milling extends to the variety of materials that can be machined. From metals like aluminum and steel to plastics and composites, CNC milling services can handle a wide range of materials, providing designers with the freedom to select the most appropriate material for their product without being constrained by the limitations of traditional machining methods. This material flexibility further enhances product design by allowing for the integration of different materials to achieve desired properties such as strength, weight, or thermal resistance.

Another aspect where CNC milling services contribute to product design is through rapid prototyping. The ability to quickly produce a prototype is invaluable in the design process, as it allows for testing and refinement before full-scale production begins. CNC milling can accelerate this process by creating precise prototypes that accurately

Reducing Waste and Cost: The Economic Benefits of CNC Milling in Production

The manufacturing industry is a cornerstone of the global economy, and its success hinges on the ability to produce high-quality products efficiently and cost-effectively. One of the most significant advancements in this sector has been the adoption of CNC milling services, which have revolutionized the way manufacturers approach production. CNC milling, or Computer Numerical Control milling, is a technology that allows for precise control of machine tools via a computer, enabling the production of complex parts with high accuracy and repeatability. The economic benefits of CNC milling in production are manifold, particularly when it comes to reducing waste and cost, which are critical factors in maintaining a competitive edge in today’s market.

Firstly, CNC milling services have dramatically reduced material waste. Traditional manufacturing methods often involve manual measurements and cuts, which can lead to human error and inconsistencies. In contrast, CNC machines follow exact specifications programmed into their systems, ensuring that each cut is as close to perfect as possible. This precision minimizes the amount of material that is cut away and discarded, allowing manufacturers to make the most of their raw materials. As a result, companies can see a significant decrease in material costs, which is especially important in an era where resource conservation is not just economically savvy but also environmentally responsible.

Moreover, the high accuracy of CNC milling translates into fewer errors and defects in the final products. This level of quality control is essential for maintaining a brand’s reputation for reliability and for reducing the costs associated with rework or scrapping defective parts. By delivering consistently high-quality components, manufacturers can avoid the expenses and logistical headaches that come with product recalls or customer dissatisfaction. This reliability also opens doors to new markets and customers who demand precision-engineered products, further expanding a company’s potential for growth.

Another economic benefit of CNC milling services is the reduction in labor costs. CNC machines can operate autonomously once programmed, which means they require less manual oversight than traditional machines. This automation allows skilled workers to focus on other critical tasks, increasing overall productivity. Additionally, CNC milling

Advancements in CNC Technology: Impact on the Future of Manufacturing Industry

The manufacturing industry has long been the backbone of economic growth, driving innovation and productivity across various sectors. Central to this progress is the evolution of machining techniques, particularly CNC milling services, which have revolutionized how manufacturers approach production. CNC, or Computer Numerical Control, milling is a subtractive manufacturing process that uses computerized controls and rotating multi-point cutting tools to progressively remove material from a workpiece, shaping it into the desired form. The importance of CNC milling services in the manufacturing industry cannot be overstated, as they offer unparalleled precision, efficiency, and repeatability, which are critical in today’s competitive market.

Advancements in CNC technology have had a profound impact on the future of the manufacturing industry. The integration of sophisticated software and hardware has enabled machines to execute complex cuts and intricate designs that were once considered impossible or too costly to produce. This leap in capability has opened up new avenues for innovation, allowing manufacturers to create components with tighter tolerances and better surface finishes. As a result, industries such as aerospace, automotive, and medical devices, which demand high levels of accuracy and consistency, have greatly benefited from the enhanced capabilities of CNC milling services.

Moreover, the automation aspect of CNC machining reduces the likelihood of human error and the variability that comes with manual machining. This consistency is crucial for maintaining quality control across large production runs, ensuring that every part meets stringent specifications. The ability to produce high-quality parts reliably is a significant competitive advantage, as it leads to increased customer satisfaction and loyalty.

The efficiency of CNC milling services also plays a pivotal role in reducing production times and costs. With computerized control, machines can operate around the clock with minimal supervision, thus maximizing output and reducing labor costs. Additionally, the speed at which CNC mills can produce parts means that manufacturers can respond more quickly to market demands and reduce time-to-market for new products. This responsiveness is essential in an era where consumer preferences are constantly changing and the pressure to innovate is relentless.

Media Contact

Company Name: Tik Precision Manufacturing Co.,Limited

Email: Send Email

City: Kowloon

Country: HongKong

Website: www.tikprecision.com