Zetamotion Ltd., a leader in AI-powered quality inspection, has released the results of the first year of deployment in partnership with Aviation Glass. The successful implementation of Zetamotion’s flagship platform, Spectron™, demonstrated the transformative power of automation in aviation manufacturing. This milestone marks a major breakthrough for AI-driven quality control in high-precision industries, and Zetamotion is now offering free feasibility checks to manufacturers looking to explore similar benefits in their own production lines.

Aviation Glass: Raising the Bar in Aircraft Interior Quality

In the aviation industry, where even minor imperfections can lead to major consequences, quality assurance must be both fast and fail-proof. Aviation Glass, known for its cutting-edge glass solutions for aircraft interiors, partnered with Zetamotion to enhance their inspection process using Spectron™, an AI-powered quality control platform that detects, measures, and classifies manufacturing defects and other QC parameters in real time.

“We’ve drastically reduced inspection times while maintaining the highest standards of quality, allowing us to focus more on innovation and growth,” said Jaap Wiersema, Managing Director of Aviation Glass.

Spectron™ Implementation: From Manual to Instantaneous Inspection

During its first year of deployment, Spectron™ replaced traditional manual inspections with real-time AI analysis, reducing inspection times from over 20 minutes per panel to mere seconds. The platform scanned more than 2,500 glass panels, evaluating over 300,000 potential defect anomalies with an impressive 99.99% accuracy in detecting, measuring and categorising actual defects.

Results That Matter: Time Saved, Yield Increased, Quality Elevated

The collaboration produced measurable gains:

- 1,200+ hours saved annually by streamlining inspections.

- ~5% increase in production yield, driven by actionable insights from defect trend analysis.

- 46 product variants and 30 unique pass/fail criteria seamlessly supported by Spectron™’s scalability.

- Faster time-to-market and reduced recall claims, thanks to complete product records and defect traceability.

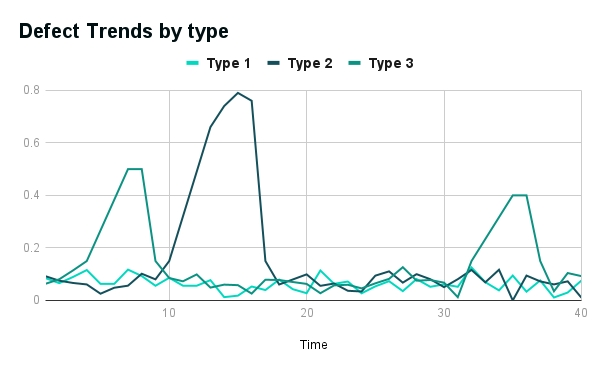

Figure 1: Analyzing trends in specific defect types allows for swift corrective measures and offers valuable insights for future maintenance and troubleshooting.

“Manual inspectors usually stop inspecting once a fail condition is met, which means they miss broader patterns,” Wilhelm Klein, CEO of Zetamotion, explained. “Spectron™ not only captures 100% inspection coverage but turns data into strategic improvements.”

Human-in-the-Loop AI That Learns and Evolves

One of Spectron™’s most innovative features is its ability to mimic human learning through synthetic data. Much like training a new quality control employee, the system learns from just one onboarding scan, adapting quickly to new product variants without the need for thousands of labeled images.

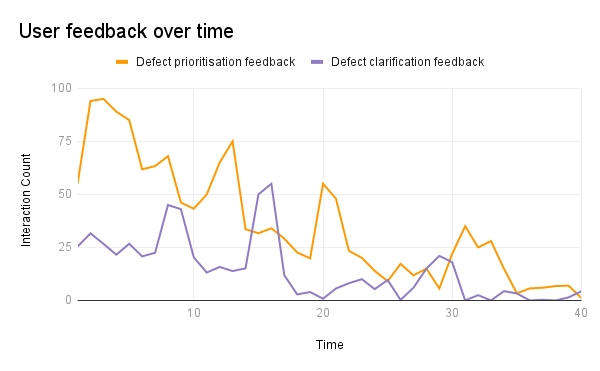

This hybrid approach allowed Aviation Glass to address complex defect types across variable materials. By leveraging Spectron™’s AI Assistant and built-in human-in-the-loop capabilities, the team could easily capture outlier defects and fine-tune inspection workflows, even upgrading camera systems in a single day after real-time issue detection.

Visualizing Defects with Actionable Data

With complete digital twinning of QC parameters and data analytics built into the system, Aviation Glass gained new visibility into its operations. Trend graphs showed how defect prioritization evolved over time, helping engineers rapidly implement root cause corrections and preventative maintenance.

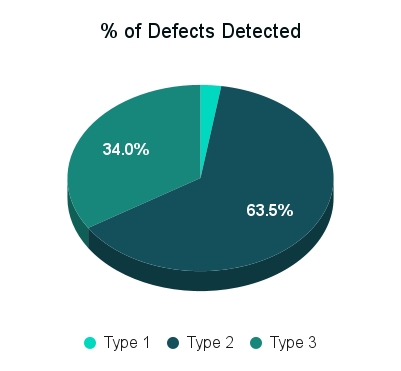

Figure 2: Spectron’s defect trend analytics reveal a notably higher frequency of Type 2 defects compared to Types 1 and 3, signaling the need for targeted root cause analysis.

Figure 3: The graph shows how ongoing defect prioritization and feedback helped Spectron integrate human insight over time.

Zetamotion’s Broader Vision: Scaling Smart QC Across Industries

Founded in 2019 and headquartered in Dartmouth, England, Zetamotion Ltd. develops and deploys intelligent QC platforms for industries requiring ultra-precise quality assurance. Their Spectron™ platform integrates seamlessly into existing workflows and has been deployed in aviation, electronics, automotive, and advanced manufacturing sectors.

“Spectron’s goal is simple: deliver lightning-fast inspection that adapts as quickly as your production line evolves,” said Hai Anh Hoang, Tech Lead at Zetamotion.

CEO Wilhelm Klein added, “We built Spectron to help manufacturers get close to what a factory can look like in the future. Not only via advanced tech, but also with a team that arrives with time, dedication and respect for your craft. Our goal is to understand what you do and what you need, and from there build automation which truly augments and transforms.”

Wilhelm Klein, CEO of Zetamotion

Why Choose Spectron™: Key Advantages at a Glance

- 99.99% accuracy in defect detection—no fine-tuning or manual labeling required.

- One onboarding scan to start inspecting a new product variant.

- Projects can get started in under two weeks, with product variants onboarded in less than 24 hours.

- Integrated digital twinning, enabling full product inspection history and process analytics.

- Sustainable value through reduced energy, scrap, and labor costs.

Beyond performance, Zetamotion ensures full data security, offering encrypted, standards-compliant connectivity with ERP, SCADA, and other factory systems.

Open for New Partnerships: Free Feasibility Checks Available

Zetamotion is inviting manufacturers from all industries, including aerospace, automotive, defence, and composites manufacturing, as well as others seeking to enhance their inspection processes, to explore new partnerships.

Companies can now request a complimentary feasibility check to assess Spectron™’s potential impact on their production lines.

With proven success in demanding environments, Zetamotion is ready to help more organizations achieve better quality, higher yield, and smarter operations.

To read the case study findings, visit here.

About Zetamotion Ltd.

Founded in 2019, Zetamotion Ltd. is a UK-based technology company specializing in AI-powered quality control platforms. The company is incorporated under Company No. 12077215 and operates out of Dartmouth, England. With customers in high-tech manufacturing sectors around the globe, Zetamotion is committed to delivering scalable, automated, and intelligent QC systems that reduce waste, elevate quality, and empower data-driven decision-making.

To learn more, visit https://zetamotion.com/ or email contact@zetamotion.com

Media Contact

Company Name: Zetamotion Ltd.

Contact Person: Wilhelm Klein, CEO

Email: Send Email

Country: United Kingdom

Website: zetamotion.com