Precision is the foundation of modern sign making. Whether cutting vinyl graphics, reflective films, PVC sheets, or composite boards, the quality of the blade directly determines edge clarity, dimensional accuracy, and production efficiency. As digital cutting systems continue to replace manual and mechanical methods, tungsten carbide digital blades have become a critical component in achieving consistent, high-quality results.

Digital Cutting Demands a Different Kind of Blade

Unlike traditional cutting, digital sign cutting relies on controlled, high-frequency movements guided by software. The blade is expected to follow complex paths, execute tight corners, and maintain accuracy over long production runs.

Standard steel blades often lose sharpness quickly under these conditions. Edge wear leads to dragging, burrs, and material tearing—problems that directly affect finished sign quality.

Tungsten carbide blades are designed to meet these demands.

Edge Stability Makes the Difference

Tungsten carbide is significantly harder than conventional tool steels. This inherent hardness allows digital blades to maintain a stable, sharp cutting edge even after extended use.

In practical terms:

Clean edges on vinyl and film remain consistent from the first cut to the last

Fine details, small text, and sharp corners are cut accurately

Material distortion caused by dull edges is minimized

For sign makers producing high-precision graphics, this edge stability translates directly into fewer rejects and higher customer satisfaction.

Consistency Across a Wide Range of Materials

Sign shops rarely cut just one material. A typical workflow may include:

Self-adhesive vinyl

Reflective sheeting

PET films

Foam board

Thin PVC or composite panels

Tungsten carbide digital blades perform reliably across this material range. Their wear resistance allows them to handle both soft and mildly abrasive substrates without frequent blade changes.

Compared to steel blades, carbide blades maintain cutting depth and accuracy longer, reducing the need for constant recalibration of the cutting system.

Reduced Downtime, Higher Productivity

Blade changes interrupt production. In digital cutting, frequent blade replacement also introduces variability, as each new blade may require fine adjustments.

Because tungsten carbide blades last significantly longer:Blade change intervals are extended;Machine uptime increases;Operators spend less time on setup and correction

For sign makers working under tight deadlines, this reliability is a practical advantage, not just a technical one.

Designed for Professional Results

At Huaxin Cemented Carbide, tungsten carbide digital blades are engineered specifically for precision cutting applications. Blade geometry, edge finish, and material grade are optimized to balance hardness and toughness, ensuring clean cuts without chipping or premature wear.

The result is a blade that performs consistently in real production environments—not just in short tests.

Huaxin Cemented Carbide continues to develop tungsten carbide blade solutions engineered specifically for modern staple fiber cutting challenges, where true hardness is built into the material itself.

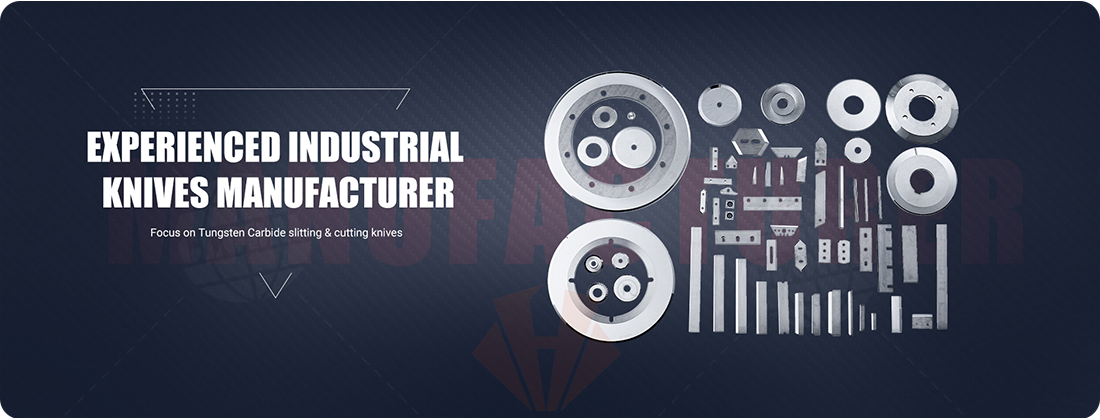

About Huaxin:Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Staple fiber cutter blade

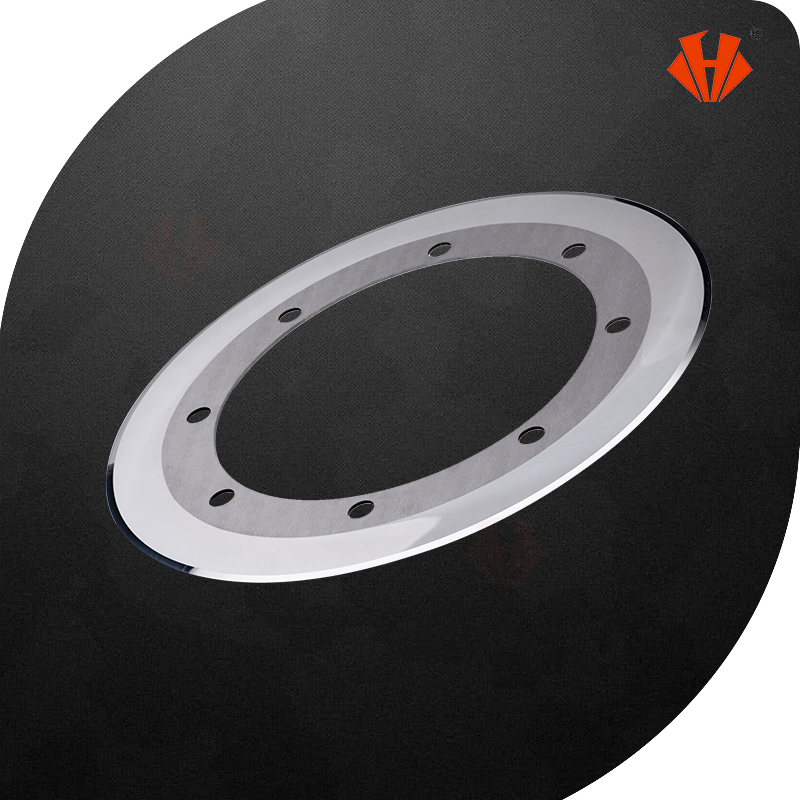

Circular knives for cigarette filter slitting

Circular knives for corrugated packaging industry

Carbide blades for woodworking

Carbide blades for tape, thin film industry

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry custom-engineered bladesLeading manufacturer of industrial blades

Click to contact for custom industrial knives

Media Contact

Company Name: Chengdu HUAXIN cemented carbide Co., Ltd

Email: Send Email

Country: China

Website: https://www.huaxincarbide.com/