Asv Tracks set a new standard for heavy equipment stability and safety. Their Posi-Track design offers up to four times more ground contact points than steel tracks. This increases flotation and traction, reduces ground pressure, and extends service life by up to 1,000 hours. Operators experience greater control and confidence.

Key Takeaways

- ASV Tracks use advanced rubber and a unique Posi-Track design to provide superior traction, stability, and longer track life, making heavy equipment safer and more reliable on all terrains.

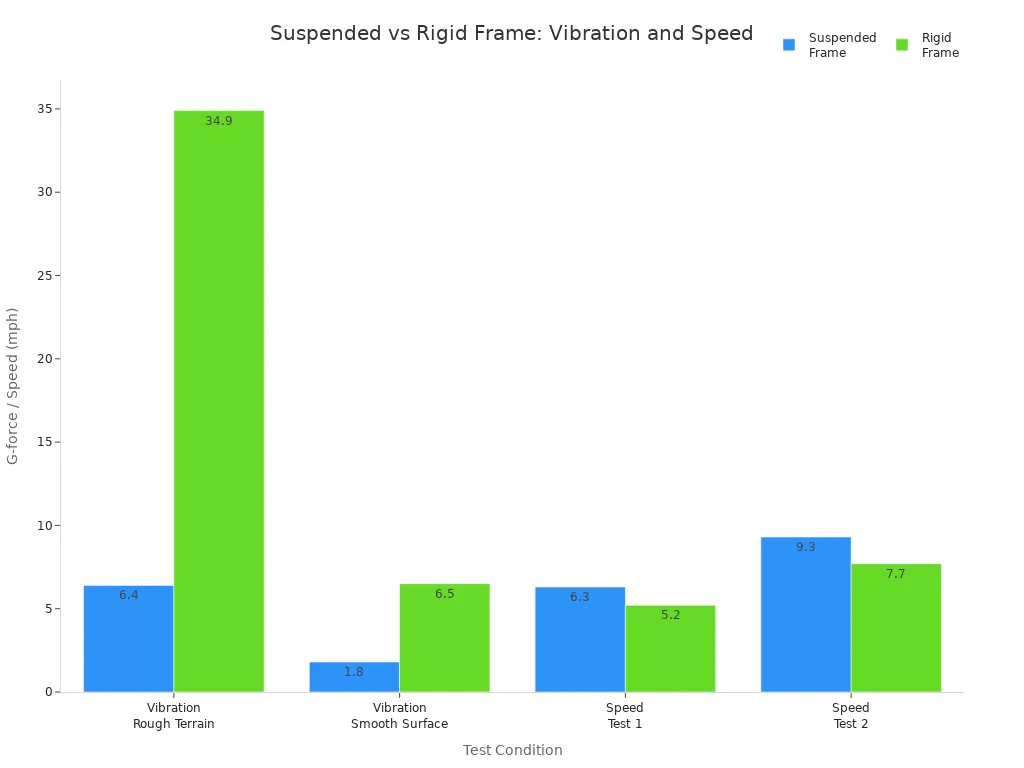

- The fully suspended frame and multi-layer construction reduce vibrations and operator fatigue, improving comfort and productivity during long work hours.

- ASV Tracks evenly distribute weight and lower ground pressure, protecting sensitive environments while allowing machines to work efficiently in tough conditions like mud, snow, and steep slopes.

ASV Tracks: Unique Features and Engineering

Advanced Rubber Construction and Durability

ASV Tracks stand out with their advanced rubber construction. The tracks use multi-layer reinforced rubber, embedded with high-tensile poly-cords that run the length of each track. This design resists stretching, cracking, and damage, even in harsh environments. Unlike traditional tracks, ASV Tracks contain no steel cords, which means no rust or corrosion. Seven layers of puncture, cut, and stretch-resistant materials maximize durability. Specialized rubber compounds extend wear resistance, while a single-cure manufacturing process removes weak points. Proper maintenance can extend track life up to 5,000 hours, as shown in field tests.

| Maintenance Condition | Average Track Lifespan (hours) |

|---|---|

| Neglected / Poorly Maintained | 500 |

| Typical Maintenance | 2,000 |

| Well Maintained (Regular Inspection) | Up to 5,000 |

Completely Suspended Frame and Ride Quality

A completely suspended frame system sets ASV Tracks apart from other heavy equipment track systems. Rubber-on-rubber contact points absorb shocks and reduce vibration, lowering dynamic stress on both the tracks and the machine. Independent torsion axles and bogie wheels flex with the track, delivering a smoother ride. Operators experience less vibration and fatigue, which leads to increased comfort and productivity. The suspended frame also reduces material loss and component wear, allowing faster speeds over rough terrain and improving overall ride quality.

All-Terrain, All-Season Tread Design

ASV Tracks feature an all-terrain, all-season tread pattern that delivers superior traction on mud, snow, gravel, and sand. The tread design self-cleans and pushes out debris, preventing clogging and maintaining grip. Operators benefit from reliable traction and stability on steep slopes and slippery surfaces. The tracks’ wider footprint reduces ground pressure, prevents sinking, and minimizes soil compaction. This design extends the workable season by up to 12 days and reduces track-related expenses by 32%. The result is uninterrupted year-round operation and enhanced safety.

Posi-Track Undercarriage Technology

The Posi-Track undercarriage system is a hallmark of ASV engineering. It uses a fully suspended frame with independent torsion axles, rubber-on-rubber contact points, and high-strength polyester wire reinforcement. The open-rail design allows debris to fall out, reducing maintenance needs. The system provides up to four times more ground contact points than steel-embedded rubber models, improving flotation and stability. Operators enjoy improved comfort, reduced fatigue, and virtually no risk of track derailment. The Posi-Track system extends track life to about 1,200 hours and reduces annual replacements to just once per year, making it a smart investment for any heavy equipment owner.

ASV Tracks: Real-World Safety and Stability Benefits

Superior Traction and Reduced Slippage

Asv Tracks deliver outstanding traction, which helps prevent slippage and keeps heavy equipment stable on any surface. The patented Posi-Track system maintains strong ground contact, even on soft or uneven terrain. This design reduces the risk of tipping or rollovers, keeping operators safe and machines working. The tracks grip mud, snow, and gravel, so operators can work confidently in all weather. Fewer slips mean fewer accidents and less downtime. The rubber tracks also lower ground pressure, which protects the worksite and keeps machines moving smoothly.

Operators notice fewer interruptions and safer job sites when using Asv Tracks. The advanced tread design and flexible rubber structure help machines stay steady, even on steep slopes or loose ground.

Even Weight Distribution and Lower Ground Pressure

Asv Tracks spread the weight of heavy equipment over a larger area. This even weight distribution keeps machines from sinking into soft soil or damaging sensitive ground. The Posi-Track system uses more wheels per track than other brands, which helps balance the load and reduce ground pressure. For example, the ASV RT-65 model achieves ground pressure as low as 4.2 psi, making it ideal for wetlands, turf, and other delicate environments.

- 15-inch-wide rubber tracks increase ground contact.

- More wheels powering each track distribute pressure evenly.

- Smoother rides and less ground disturbance protect the environment.

Rubber tracks allow operators to work in places where traditional equipment would cause damage. Landscapers, farmers, and construction crews can finish jobs without harming lawns, wetlands, or wildlife areas.

Enhanced Operator Comfort and Protection

Operator comfort and safety matter on every job site. Asv Tracks feature a fully suspended frame and advanced suspension system that absorb shocks and reduce vibrations. Operators report feeling less tired and more focused, even after long hours on rough terrain. The design supports neutral body positioning and reduces repetitive motions, which lowers the risk of injury.

| Metric | Rubber Composite Track Systems | Traditional Track Systems |

|---|---|---|

| Vertical Vibration Reduction | Up to 96% | N/A |

| Ground-borne Noise Reduction | 10.6 to 18.6 dB | N/A |

| Peak Acceleration Reduction | 38.35% to 66.23% | N/A |

Machines like the ASV RT-135 Forestry loader also include ROPS and FOPS safety structures. These features protect operators from rollovers and falling objects, reducing accident risks. Comfortable, quiet cabs help operators stay alert and productive all day.

Reliable Performance on Challenging Terrain

Asv Tracks prove their value on steep, uneven, or loose terrain. The advanced tread pattern grips slopes and loose surfaces, keeping machines stable and safe. Reinforced rubber and high-strength polyester wires prevent stretching and derailment, even under heavy loads. Operators can trust their equipment to perform in mud, snow, sand, or rocky areas.

- Tracks maintain grip on steep inclines and muddy fields.

- Wide footprint prevents sinking or sliding.

- Enhanced maneuverability allows safe operation in tight spaces.

The tracks resist cracking in cold and softening in heat, so they work year-round. Regular inspection and cleaning keep them reliable, reducing emergency repairs and downtime. Asv Tracks help operators finish tough jobs safely, no matter the conditions.

Asv Rubber Tracks combine advanced materials and smart engineering to deliver safer, more stable heavy equipment. Operators gain confidence and reduce risk on any terrain. Owners see less downtime and higher productivity.

Experts and owners agree: these tracks improve traction, comfort, and long-term value for every job.

FAQ

How do ASV tracks improve safety on job sites?

ASV tracks give machines better traction and stability. Operators stay safer. The risk of accidents drops. Teams work with more confidence every day.

Can ASV tracks handle tough weather and terrain?

Yes. ASV tracks use all-terrain, all-season tread. Machines keep moving in mud, snow, or sand. Operators finish jobs on time, no matter the weather.

Why should equipment owners choose ASV tracks?

Owners see less downtime and longer track life. ASV tracks protect machines and job sites. Investing in ASV tracks means better performance and higher profits.

Media Contact

Company Name: Gator Track Co., Ltd.

Email: Send Email

Country: China

Website: https://www.gatortrack.com/