I see the future of Heat Exchangers shaped by breakthroughs in energy efficiency, digital intelligence, and sustainable materials. The global plate & frame heat exchanger market will reachUSD 10.50 billion by 2030, fueled by industries demanding better performance. Brands like senjun, known for advanced solutions such as the Copper Fin Heat Exchanger, lead this transformation. Ningbo Senjun New Materials Co., Ltd. specializes in wire tube condensers and copper aluminum fin heat exchangers for appliances like refrigerators, freezers, and medical equipment.

Key Takeaways

- Heat exchangers in 2030 will be more energy-efficient, using advanced technologies like additive manufacturing, nanofluids, and smart sensors to save energy and reduce maintenance costs.

- Compact, modular designs with corrosion-resistant materials will make heat exchangers easier to install, maintain, and customize for different industries and spaces.

- Smart integration with IIoT and real-time monitoring will enable predictive maintenance and data-driven optimization, improving performance and lowering energy waste.

Enhanced Energy Efficiency Next-Generation Heat Transfer Technologies

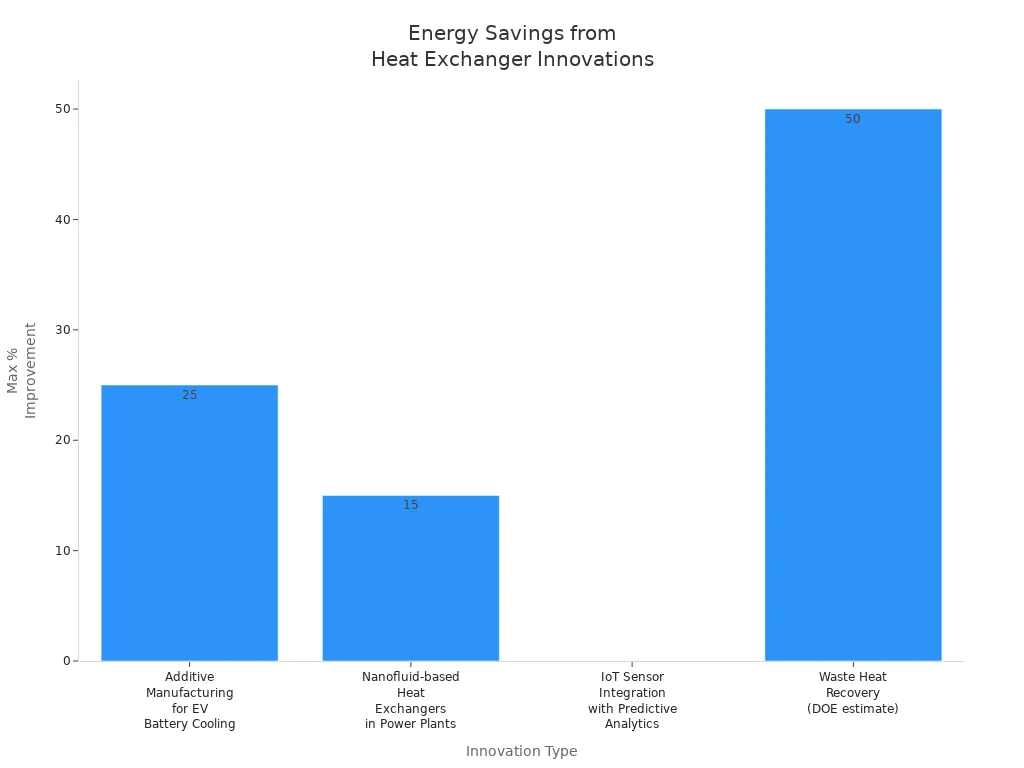

I see the future of heat exchangers driven by remarkable advances in heat transfer technology. Additive manufacturing now allows me to design complex internal structures that boost thermal performance, especially for electric vehicle battery cooling. Nanofluid-based heat exchangers in power plants deliver up to 15% higher heat transfer efficiency. These innovations help industries achieve more with less energy. I also rely on IoT sensor integration and predictive analytics to monitor system health and prevent unplanned downtime. This approach not only saves energy but also reduces maintenance costs.

| Innovation Type | Measurable Improvement | Impact on Energy Savings/Efficiency |

|---|---|---|

| Additive Manufacturing for EV Battery Cooling | Up to 25% improved thermal performance | Enhances cooling efficiency, reducing energy consumption |

| Nanofluid-based Heat Exchangers in Power Plants | Up to 15% increase in heat transfer efficiency | Enables higher power output without extra energy input |

| IoT Sensor Integration with Predictive Analytics | Significant reduction in unplanned downtime | Lowers maintenance costs and improves operational efficiency |

| Waste Heat Recovery (DOE estimate) | 20-50% of industrial energy input lost as waste heat | Recovery translates directly to fuel savings and reduced energy consumption |

Reduced Energy Loss and Waste

I focus on minimizing energy loss and waste in every heat exchanger system I design. Today’s best practices include:

- Optimization of heat recovery systems to capture and reuse waste heat.

- Adoption of hybrid heat recovery systems, which combine multiple technologies for greater efficiency.

- Careful consideration of backpressure effects, especially when recovering energy from exhaust gases in engines and generators.

- Integration with Rankine cycles and thermoelectric generators, which expands waste heat recovery across automotive, residential, and industrial sectors.

By 2030, I expect these strategies to become standard, making heat exchangers more efficient and sustainable than ever before.

Compact and Modular Designs

Space-Saving Solutions

I see a clear trend toward smaller, more efficient heat exchangers. Compact designs now dominate the industry. I often choose corrosion-resistant engineering plastics for their chemical resistance and easy cleaning. Thin-walled tube bundles help me achieve a compact shape while still delivering high heat transfer. I rely on lightweight construction to make handling and installation easier. These features allow me to fit powerful heat exchangers into tight spaces, such as inside medical refrigerators or display cabinets.

- Corrosion-resistant plastics make cleaning simple and extend product life.

- Thin-walled tubes boost heat transfer without adding bulk.

- Modular block units arrive ready for quick assembly by a small team.

- I can scale the width and height by adding or removing elements.

- Lightweight parts simplify transport and setup.

- Smooth tube geometry and improved water drainage keep systems efficient.

These design choices help me save valuable floor space and deliver reliable performance.

Plug-and-Play Modularity

I value modularity because it gives me flexibility. Modular heat exchangers let me adapt to changing needs. I can integrate individual coils or use ready-to-install units with housing, cleaning devices, and droplet separators. This approach supports seamless scalability. If I need more capacity, I simply add more modules. If I want to upgrade or maintain a system, I swap out parts quickly. Plug-and-play modularity means I can customize solutions for any application, from freezers to industrial dehumidifiers. This flexibility keeps my operations efficient and future-ready.

Advanced Materials and Copper Fin Heat ExchangerCorrosion-Resistant Alloys and Composites

I always look for new materials that make heat exchangers last longer and work better. Today, I see more engineers using advanced materials in their designs:

- Ceramics handle very high temperatures and keep their strength.

- Composites help fight corrosion, so the equipment stays clean and safe.

- Advanced alloys work well in places with both heat and chemicals, giving strong performance and better thermal flow.

Recently, I have seen big improvements in glass-lined steel tubes. This material combines the strength of steel with the chemical resistance of glass. Modern glass-lined steel heat exchangers resist corrosion, last longer, and are easy to clean. They also help capture low-temperature waste heat, which boosts efficiency by up to 12% in power plants. I find these advances especially useful in industries like pharmaceuticals and chemical processing.

The Role of Copper Fin Heat Exchanger in 2030

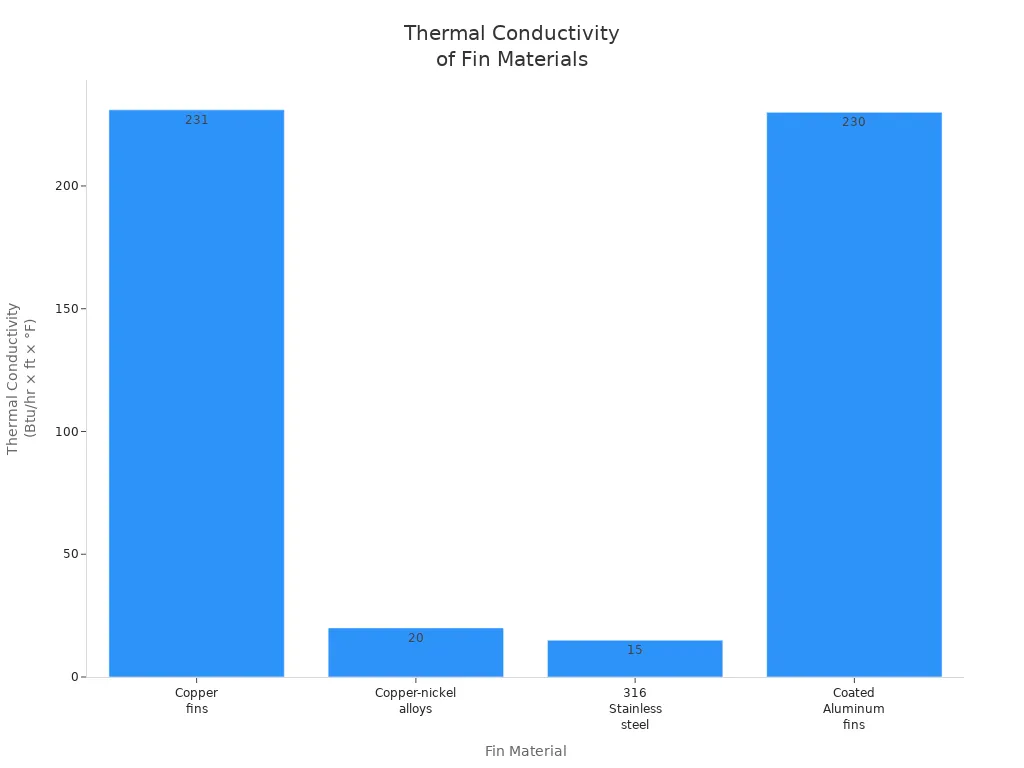

I believe the Copper Fin Heat Exchanger will remain a key player in the market by 2030. It stands out for its high thermal conductivity and cost-effectiveness. When I compare different fin materials, I see clear differences:

| Fin Material | Thermal Conductivity (Btu/hr × ft × °F) | Corrosion Resistance & Lifespan Characteristics | Efficiency vs Lifespan Tradeoff |

|---|---|---|---|

| Copper fins | 231 (highest, 60% greater than aluminum) | Moderate corrosion resistance; forms protective patina but vulnerable to aggressive corrosives like acid rain; shorter lifespan in harsh acidic environments | Highest heat transfer efficiency but limited lifespan in corrosive industrial settings |

| Copper-nickel alloys | 17 – 23 (much lower than copper) | Excellent corrosion resistance, especially in marine environments due to protective surface film; longer lifespan despite lower efficiency | Lower efficiency but superior durability and corrosion resistance, ideal for marine/harsh environments |

| 316 Stainless steel | 13 – 17 (lowest among compared materials) | Excellent corrosion resistance, especially against chlorides and reducing acids; very durable and long lifespan | Poor heat transfer efficiency but prioritized for lifespan and resilience in harsh environments |

| Coated Aluminum fins (Heresite, E-coated) | Close to bare aluminum and copper (less than 1% reduction) | Very good corrosion resistance, suitable for marine and aggressive atmospheres; coatings pass rigorous corrosion tests | Good balance of heat transfer efficiency and enhanced corrosion resistance, suitable for environments needing both |

I see several reasons why the Copper Fin Heat Exchanger will stay important:

- It costs less to make than other tube-fin types.

- It offers top energy efficiency, which matters as energy prices rise.

- It uses copper, a major raw material, so price changes can affect costs.

- New technology keeps making these exchangers more durable and efficient.

I expect the Copper Fin Heat Exchanger to play a big role in energy-sensitive fields like HVAC, refrigeration, and industrial cooling. Companies like senjun continue to push these innovations forward.

The Rise of Plate Heat ExchangersImproved Performance in Smaller Footprints

I have seen plate heat exchangers become the top choice for many industries. Their design uses thin, corrugated plates stacked together. This structure gives them a much smaller footprint than traditional shell and tube models. I can fit these units into tight spaces, which helps when I work in crowded mechanical rooms or compact refrigeration systems. The compact size also means I use less material, which lowers costs and makes installation easier. When I need to boost performance, I simply add more plates. This modular approach lets me adapt quickly to new demands.

Tip: Plate heat exchangers make maintenance simple. I can remove the plates for cleaning or inspection without taking apart the whole system.

Versatility Across Industries

I rely on plate heat exchangers because they work well in many different settings. Their flexible design allows me to adjust the number of plates for each application. I use them in food processing, HVAC, and even medical refrigeration. The removable plates help me keep systems clean, which is important in industries with strict hygiene rules. I can also change the configuration to handle different fluids or temperatures. This versatility means I do not need a new unit for every job. I trust plate heat exchangers to deliver reliable performance wherever I need them.

- Compact design fits small spaces

- Modular plates allow easy upgrades

- Simple maintenance supports long-term use

- Suitable for many industries, from food to healthcare

IIoT and Smart Integration

Real-Time Monitoring and Predictive Maintenance

I see the industrial world moving quickly toward smart heat exchangers. The adoption of IIoT-enabled heat exchangers grows every year. More companies now use sensors and control systems to track performance in real time. This trend comes from the need for better precision, higher efficiency, and energy savings. Automation and digitalization push this change forward. I notice that some smaller businesses hesitate because of higher upfront costs and complex setups. Still, the overall direction is clear. IIoT integration is becoming the new standard.

When I use real-time monitoring, I gain several important advantages:

- I can watch the health of my heat exchangers at all times. This helps me keep them efficient and cut down on energy use.

- I get key data on performance, fouling, and leaks. This information keeps my systems safe.

- I measure flow, temperature, and pressure. Early warnings let me plan cleanings before problems grow.

- I spot leaks fast with water-quality sensors. This protects the environment and my product quality.

- I use predictive maintenance tools to avoid sudden shutdowns. This keeps my operations smooth.

- I receive alerts for sudden changes in temperature or pressure. This helps me prevent accidents.

These tools give me the power to act before small issues become big problems.

Data-Driven Optimization

I rely on data to make my heat exchangers smarter. IIoT systems collect huge amounts of information every day. I use this data to spot trends, find weak points, and improve my processes. With smart analytics, I can adjust settings for the best performance. I see energy use drop and system life increase. I also use data to compare different units and choose the best designs for each job. This approach helps me save money and meet strict sustainability goals. By 2030, I expect every heat exchanger I use to come with built-in intelligence, making my work more efficient and reliable than ever before.

Adoption of Heat Recovery Systems Waste Heat Utilization

I see waste heat as a valuable resource that many industries overlook. When I design heat exchanger systems, I focus on capturing and reusing this energy. For example, I worked with a food production facility that installed a condensing heat recovery system. This upgrade saved them between 57,282 and 107,063 therms of natural gas each year. These numbers show how much energy we can save by using waste heat utilization technologies. I believe that by 2030, more factories and commercial buildings will use similar systems to cut costs and reduce emissions.

I often recommend heat exchangers that recover heat from exhaust gases, cooling water, or even refrigeration cycles. These systems help lower fuel use and make operations more efficient. I also see companies like senjun leading the way by developing advanced heat exchangers for refrigerators, freezers, and medical equipment. Their products help businesses use less energy and protect the environment.

Integration with Renewable Energy

I believe that integrating heat exchangers with renewable energy systems is the next big step. I use several methods to make this work:

- I choose counterflow heat exchanger configurations to keep temperature differences high and efficiency strong.

- I set up cleaning schedules and digital monitoring tools to prevent fouling and keep systems running smoothly.

- I replace old shell-and-tube exchangers with compact plate heat exchangers, which boost heat transfer and save space.

- I select materials that match the fluids, pressures, and temperatures in each system.

- I plan for easy maintenance and low emissions to support sustainability.

I have seen innovative designs that combine convection and radiation heat transfer in biomass energy systems. By using Computational Fluid Dynamics, I optimize plate shapes and baffle spacing. This approach has improved temperature performance by over 4% and increased overall efficiency. These advances help us get more clean energy from renewable sources and move toward a greener future.

Customization for Niche ApplicationsIndustry-Specific Solutions

I see that every industry has unique needs when it comes to heat exchangers. In pharmaceuticals, I focus on compact and modular designs. These save space and make installation faster. I choose corrosion-resistant materials like stainless steel and titanium. These materials help me meet strict sanitary rules and ensure long-lasting performance. In data centers, I use similar compact designs to manage heat efficiently. I add smart monitoring systems with IoT sensors. These systems give me real-time data and help me spot problems before they grow. I notice that digitalization and predictive maintenance are now standard features. They help me keep systems running smoothly and meet the high standards of Industry 4.0. I always pay attention to regulatory demands and the need for skilled workers. Customization helps me deliver solutions that fit each industry perfectly.

Rapid Prototyping and On-Demand Manufacturing

I rely on rapid prototyping to speed up the development of new heat exchanger designs. This approach uses AI-driven optimization and advanced 3D printing. Here is how it helps me:

- AI and computational fluid dynamics let me explore many design options quickly.

- I improve thermal effectiveness by about 10% compared to older methods.

- Multi-objective optimization gives me designs with 54% higher power density and 35% better heat transfer per unit volume.

- I use 3D printing to create and test new designs fast, confirming my simulations.

- This process lets me move quickly from idea to finished product, saving time and resources.

- I can apply this method to many shapes, materials, and working conditions.

With these tools, I meet the demands of niche markets and deliver custom solutions faster than ever before.

senjun and Industry Leadership senjun’s Innovations in Heat Exchanger Technology

I have watched senjun set new standards in heat exchanger technology. As a leader in the field, senjun focuses on research, development, and production of advanced solutions. The company, Ningbo Senjun New Materials Co., Ltd., specializes in wire tube condensers and copper aluminum fin heat exchangers. I see their team use the latest materials and manufacturing techniques. They invest in corrosion-resistant alloys and smart designs that boost energy efficiency. Their engineers use digital tools to test and improve every product. I notice that senjun always looks for ways to make heat exchangers more compact and easier to install. They also use modular designs, which help me scale systems for different needs.

Note: senjun’s commitment to innovation means I can trust their products to meet the demands of tomorrow’s industries.

Applications Across Refrigeration and HVAC

I rely on senjun’s heat exchangers in many refrigeration and HVAC systems. Their products work in refrigerators, freezers, display cabinets, and medical ultra-low temperature refrigerators. I also use them in drinking fountains, wine cabinets, ice makers, and dehumidifiers. These applications need reliable and efficient heat transfer. senjun’s copper aluminum fin heat exchangers deliver strong performance and long service life. I see their wire tube condensers help keep systems cool and energy use low. When I choose senjun, I know I get solutions that fit both commercial and industrial needs.

- Reliable cooling for food storage

- Stable temperatures for medical equipment

- Energy savings in commercial refrigeration

I trust senjun to lead the way in heat exchanger technology for years to come.

By 2030, I expect heat exchangers to meet strict energy and environmental standards. Smarter designs and real-time monitoring will cut energy waste. The Copper Fin Heat Exchanger will help industries lower carbon emissions. I see companies like senjun leading this shift toward sustainable, cost-effective solutions.

FAQ

What makes senjun’s heat exchangers stand out in 2030?

I trust senjun for advanced materials, modular designs, and reliable performance. Their products support energy savings and fit many refrigeration and HVAC needs.

How do smart heat exchangers improve efficiency?

I use real-time monitoring and predictive maintenance. These features help me reduce downtime, optimize performance, and save energy every day.

Can I customize a heat exchanger for my industry?

- Yes, I work with rapid prototyping and modular designs.

- I tailor solutions for food, medical, or industrial applications with ease.

Media Contact

Company Name: Ningbo Senjun New Materials Co., Ltd.

Email: Send Email

Phone: +86-574-83073262

Address:3rd Floor, Building 1, 68 Chunchao Road, Yinzhou District, Zhejiang Province

City: Ningbo

Country: China

Website: https://www.senjuncooler.com/