DDM (Digital Diagnostic Monitoring) is a technology used in optical modules. It is used to diagnose the working state of optical modules. It is a real-time parameter monitoring means of optical modules. It allows users to monitor the parameters of optical modules in real time, including received optical power, transmitted optical power, operating temperature, power supply voltage and laser bias current.

Then, compare the monitored value with the value range required by the optical module under normal working conditions. If it is not within the required range, an alarm will be given. If the optical module is displayed to be in a bad condition, the switch will stop sending data, and will not send or receive data again until the optical module is in a normal condition.

The optical module DDM works based on the standard parameter values defined by the SFF-8472 protocol. The SFF-8472 protocol specifies the standard parameter values or ranges to be followed by the software and hardware of optical modules and network devices (such as switches), ensuring the interoperability of products provided by different network equipment suppliers and optical module suppliers.

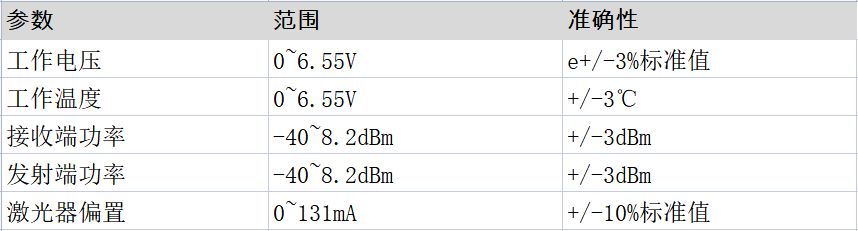

In short, a set of general OAM parameters can be shared by the entire communication industry. It is worth noting that the accuracy of some products has exceeded the requirements of the agreement. The following table shows the parameter standards of SFF-8472 protocol for optical modules.

Media Contact

Company Name: Shenzhen HDV Phoelectron Technology LTD

Email: Send Email

Country: China

Website: https://www.hdv-fiber.com/