IntroductionIn the rapidly evolving landscape of industrial automation, three-axis servo robots have emerged as versatile and efficient tools that cater to a wide range of manufacturing applications. These robots are designed to operate along three linear axes—X, Y, and Z—enabling them to perform precise and repetitive tasks with high accuracy and reliability。

Understanding Three-Axis Servo Robots

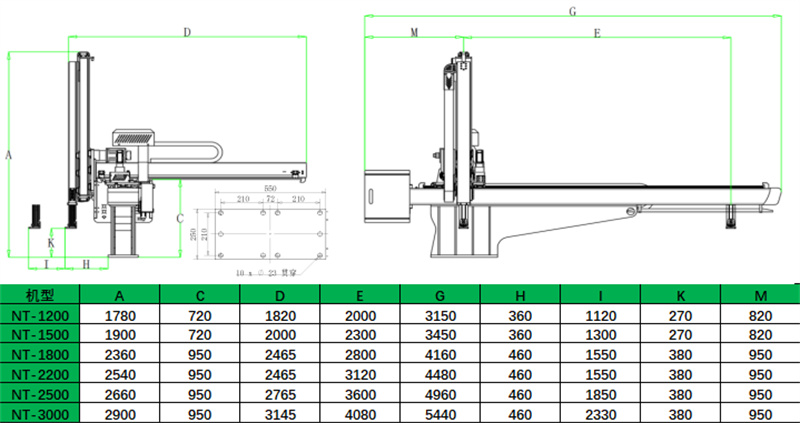

Basic Structure and MovementA three-axis servo Robot Co consists of several key components:Servo Motors: These provide the power for movement along each axis, ensuring precise control。Linear Guide Rails: These facilitate smooth and accurate movement in the X, Y, and Z directions。Controller Unit: This acts as the brain of the robot, interpreting programming instructions and managing movements。End Effectors: Tools like grippers or suction cups attached to the robot’s arm to interact with objects。

The movement of a three-axis servo robot is based on the Cartesian coordinate system, allowing it to perform linear motions within a defined workspace。This simplicity makes them highly reliable and cost-effective compared to more complex multi-Axis Robots。

Key Advantages of Three-Axis Servo Robots

High Precision: These robots can achieve sub-millimeter precision, making them ideal for tasks requiring exact positioning。Cost-Effectiveness: Their straightforward design reduces manufacturing and maintenance costs。Ease of Integration: They can be easily integrated into existing production lines with minimal changes。Reliability: With fewer moving parts, they have lower chances of mechanical failure。Energy Efficiency: Servo motors consume less energy, contributing to lower operational costs。

Typical Applications in ManufacturingInjection Molding IndustryThree-axis servo robots are extensively used in injection molding for tasks such as:Finished Product Removal: They can quickly and accurately remove finished products from molds。Nozzle Cutting: They perform precise cutting operations on injection molding nozzles。Simple Assembly: They handle basic assembly tasks, improving production efficiency。These robots significantly enhance the automation level and product quality in injection molding operations。

Palletizing and HandlingIn warehousing and logistics, three-axis servo robots play a crucial role in:Palletizing: They efficiently stack goods onto pallets with high precision。Handling: They handle heavy objects, reducing the need for manual labor and improving safety。Their strong load capacity and flexibility make them suitable for various warehousing scenarios

Electronics ManufacturingIn the electronics industry, three-axis servo robots are used for:PCB Handling and Assembly: They handle and assemble printed circuit boards with high precision。Component Placement: They place small electronic components accurately, ensuring high-quality products。Their high-precision motion control is essential for the delicate tasks involved in electronics manufacturing。

Automotive IndustryIn the automotive sector, these robots are employed for:Linear Welding: They perform precise welding operations on automotive components。Component Placement: They place parts accurately during assembly。Their ability to perform repetitive tasks with high accuracy makes them valuable in automotive manufacturing。

Medical Device ProductionThree-axis servo robots are also used in the medical device industry for:Assembly: They assemble medical devices with high precision。Packaging: They package medical devices, ensuring compliance with strict quality standards。Their reliability and precision are crucial for meeting the stringent requirements of medical device production。

Packaging and PalletizingThese robots are known for their efficiency in:Automated Packing: They sort and pack products quickly and accurately。Palletizing: They stack packed products onto pallets, optimizing warehouse space。Their repetitive motion capabilities make them ideal for these tasks, reducing labor costs and increasing throughput。

Choosing the Right Three-Axis Servo RobotSelecting the appropriate three-axis servo robot involves considering several factors:Payload Capacity: Ensure the Robot Can handle the weight of the components。Reach and Workspace Size: Match the robot’s range of motion to the operational space。Speed Requirements: Some applications demand faster cycle times。Compatibility: Consider how well the robot integrates with existing systems。Partnering with reputable manufacturers can provide additional support in programming and customization。

Media Contact

Company Name: Zhejiang Zhiyi Intelligent Robot Co., Ltd.

Email: Send Email

Country: China

Website: https://www.zhiyirobotics.com/