5G was initially commercialized in 2019. The core material, high-frequency copper-clad laminates, and other products, the upstream raw materials are basically similar to traditional CCL. After being produced by downstream PCB manufacturers as high-frequency circuit boards suitable for high-frequency environments, they are applied to base station antenna modules and power amplifiers. Modules and other equipment components are finally widely used in communication base stations (antennas, power amplifiers, low-noise amplifiers, filters, etc.), automotive auxiliary systems, aerospace technology, satellite communications, satellite TV, military radars, and other high-frequency communications fields.

5G high-frequency technology puts forward higher requirements on the circuit. Radiofrequency circuits with operating frequencies above 1GHz are generally called high-frequency circuits. In the process of mobile communication from 2G, 3G to 4G, the communication frequency band has developed from 800MHz to 2.5GHz. In the 5G era, the communication frequency band will be further improved.

The PCB board will be equipped with antenna elements, filters, and other components in terms of 5G radiofrequency. According to the requirements of the Ministry of Industry and Information Technology, it is expected that the early 5G deployment will use the 3.5GHz frequency band, and the 4G frequency band will be mainly around 2GHz. Generally, electromagnetic waves with a wavelength of 1 to 10 millimeters in the 30-300 GHz frequency band are called millimeter waves.

When 5G communication is commercially available on a large scale, millimeter wave technology guarantees better performance. Extremely wide bandwidth, the available spectrum bandwidth of the 28GHz frequency band can reach 1GHz, and the available signal bandwidth of each channel in the 60GHz frequency band can reach 2GHz. The corresponding antenna has high resolution and anti-interference performance Good, miniaturization can be achieved. Propagation attenuation in the atmosphere is faster, and close-range secure communication can be achieved.

In order to meet the needs of high frequency and high speed, as well as to deal with the problems of poor millimeter-wave penetration and fast attenuation, 5G communication equipment has the following three requirements for PCB performance:

- Low transmission loss.

- Low transmission delay.

- Precision control of high characteristic impedance. There are two ways to increase the frequency of PCB. One is that the processing process of PCB is more demanding, and the other is to use high-frequency CCL-the substrate material that meets the high-frequency application environment is called high-frequency copper clad laminate.

There are mainly two indicators of dielectric constant (Dk) and dielectric loss factor (Df) to measure the performance of high-frequency copper-clad laminate materials. The smaller the Dk and Df, the more stable, the better the performance of high-frequency and high-speed substrates. In addition, in terms of radio frequency boards, PCB boards have a larger area and more layers, requiring higher heat resistance (Tg, high-temperature modulus retention) and tighter thickness tolerances on the substrate.

There are several main high-frequency and high-speed materials for common circuit boards: hydrocarbon resin, PTFE, LCP liquid crystal polymer, PPE/PPO, etc.

Hydrocarbon resin

Hydrocarbon resin refers to polyolefin homopolymer or copolymer, including butadiene-styrene copolymer, butadiene homopolymer, styrene, homopolymer, styrene/divinylbenzene copolymer, styrene-Butadiene-divinylbenzene copolymer, etc.

1. Excellent dielectric performance: Dk≒2.4/Df≒0.0002

2. Higher heat resistance

3. Good chemical resistance

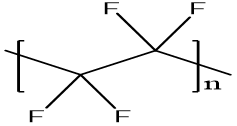

PTFE flexible membrane

The melting temperature and melt viscosity of PTFE resin is relatively high. Common commercial forms are resin dispersion, resin suspension, and resin powder. Common processing methods include molding/turning method, dipping/molding method, extrusion/molding method, etc. Due to the shortcomings of PTFE’s large linear expansion coefficient and low thermal conductivity, it needs to be enhanced and modified. The forms of modified membrane products usually include:

• PTFE + ceramic

• PTFE + glass fiber cloth

• PTFE + ceramic + glass fiber cloth

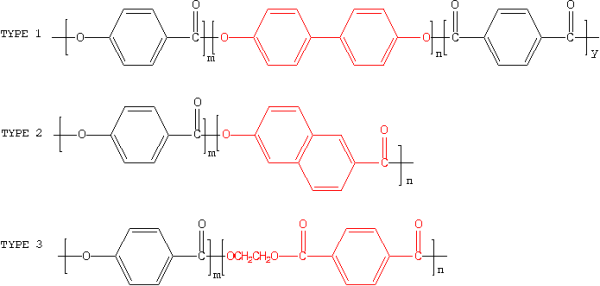

LCP liquid crystal polymer

Liquid Crystal Polymer referred to as LCP. It is a new type of high-performance special engineering plastic developed in the early 1980s. According to different formation conditions, liquid crystals can be divided into thermotropic LCP which is melted by heat, and Lyotropic LCP which is dissolved by the solvent.

After being heated and melted or dissolved by a solvent, this material will lose the solid macroscopic size, shape, hardness, rigidity, and other properties, and gain the fluidity of a liquid substance in appearance, while maintaining the orientation and order of the crystalline substance. As a result, an anisotropy is formed in the physical form, and a transition state with both liquid fluidity and an orderly arrangement of crystalline molecules is formed. This intermediate form becomes a liquid crystal state.

From the perspective of molecular design, there are three main types of commercial LCP:

- One is the copolymerization of polyphenyl ring rigid molecular monomers;

- The second is to introduce a naphthalene ring into the molecular structure;

- The third is to use aliphatic segments in the molecular chain.

According to different molecular structures, different types of LCP have different melting points. Generally speaking, their heat resistance is the type I > type II > type III.

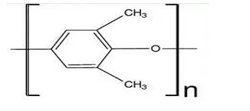

PPE/PPO

Polyphenylene ether is a high-strength engineering plastic developed in the 1960s. Its chemical name is poly 2,6-dimethyl-1,4-phenylene ether, abbreviated as PPO (Polyphenylene Oxide) or PPE (Polyphenylene ether), also known as It is polyphenylene oxide or polyphenylene ether.

The two methyl groups block the active sites of the two ortho positions of the phenol group, making it rigid。tability.heat resistance, and chemical resistance. Ether bond increases flexibility but makes heat resistance poorer.

The two methyl groups are hydrophobic non-polar groups, which reduce the water absorption and polarity of the PPO macromolecules, and block the two active points of the phenol group so that there are no hydrolyzable groups in the PPO molecular structure, and it has good water resistance and moisture absorption. Good performance, dimensional stability, and electrical insulation. A large number of rigid phenol-based aromatic rings, the rigidity of the molecular chain, and the force between the molecular chains make it difficult to internally rotate the molecular chain, resulting in its melting point, melt viscosity, fluidity, and processing difficulties.

The materials industry has ushered in a new era of 5G, and hardware carriers such as mobile phones, base stations, Internet of Things, and automobiles will have more demands and higher requirements for 5G new materials on the application side.

Media Contact

Company Name: Shenzhen RenChuangYi Electronics Co., Ltd

Email: Send Email

Phone: +86 155-8087-7877

Address:Building 4, JinFeng Industry Zone, Heping Village, Fuyong Town Bao’an District

City: Shenzhen

State: Guangdong

Country: China

Website: https://www.szrcypcb.com/