Tolerance control of mechanical components in optical lens systems represents a critical technical aspect for ensuring imaging quality, system stability, and long-term reliability. It directly influences the clarity, contrast, and consistency of the final image or video output. In modern optical systems—particularly in high-end applications such as professional photography, medical endoscopy, industrial inspection, security surveillance, and autonomous perception systems—the requirements for imaging performance are exceptionally stringent, thereby demanding increasingly precise control over mechanical structures. Tolerance management extends beyond the machining accuracy of individual parts, encompassing the entire lifecycle from design and manufacturing to assembly and environmental adaptability.

Core impacts of tolerance control:

1. Imaging Quality Assurance: The performance of an optical system is highly sensitive to the precision of the optical path. Even minor deviations in mechanical components can disrupt this delicate balance. For example, lens eccentricity may cause light rays to deviate from the intended optical axis, leading to aberrations such as coma or field curvature; lens tilt can induce astigmatism or distortion, particularly evident in wide-field or high-resolution systems. In multi-element lenses, small cumulative errors across multiple components can significantly degrade the modulation transfer function (MTF), resulting in blurred edges and loss of fine detail. Therefore, rigorous tolerance control is essential to achieve high-resolution, low-distortion imaging.

2. System Stability and Reliability: Optical lenses are often exposed to challenging environmental conditions during operation, including temperature fluctuations causing thermal expansion or contraction, mechanical shocks and vibrations during transportation or use, and humidity-induced material deformation. Insufficiently controlled mechanical fit tolerances may result in lens loosening, misalignment of the optical axis, or even structural failure. For instance, in automotive-grade lenses, repeated thermal cycling may generate stress cracks or detachment between metal retaining rings and glass elements due to mismatched coefficients of thermal expansion. Proper tolerance design ensures stable pre-load forces between components while allowing for effective release of assembly-induced stresses, thereby enhancing product durability under harsh operating conditions.

3. Optimization of Manufacturing Cost and Yield: Tolerance specification involves a fundamental engineering trade-off. While tighter tolerances theoretically enable higher precision and improved performance potential, they also impose greater demands on machining equipment, inspection protocols, and process control. For example, reducing the coaxiality tolerance of a lens barrel’s inner bore from ±0.02 mm to ±0.005 mm may necessitate transitioning from conventional turning to precision grinding, along with full inspection using coordinate measuring machines—significantly increasing unit production costs. Moreover, excessively tight tolerances can lead to higher rejection rates, lowering manufacturing yield. Conversely, overly relaxed tolerances may fail to meet the optical design’s tolerance budget, causing unacceptable variations in system-level performance. Early-stage tolerance analysis—such as Monte Carlo simulation—combined with statistical modeling of post-assembly performance distributions, enables the scientific determination of acceptable tolerance ranges, balancing core performance requirements with mass production feasibility.

Key Controlled Dimensions:

Dimensional Tolerances: These include fundamental geometric parameters such as lens outer diameter, center thickness, barrel inner diameter, and axial length. Such dimensions determine whether components can be assembled smoothly and maintain correct relative positioning. For example, an oversized lens diameter may prevent insertion into the barrel, while an undersized one may lead to wobbling or eccentric alignment. Variations in center thickness affect inter-lens air gaps, altering the system’s focal length and image plane position. Critical dimensions must be defined within rational upper and lower limits based on material characteristics, manufacturing methods, and functional needs. Incoming inspection typically employs visual examination, laser diameter measurement systems, or contact profilometers for either sampling or 100% inspection.

Geometric Tolerances: These specify spatial form and orientation constraints, including coaxiality, angularity, parallelism, and roundness. They ensure accurate shape and alignment of components in three-dimensional space. For instance, in zoom lenses or bonded multi-element assemblies, optimal performance requires that all optical surfaces align closely with a common optical axis; otherwise, visual axis drift or localized resolution loss may occur. Geometric tolerances are typically defined using datum references and GD&T (Geometric Dimensioning and Tolerancing) standards, and verified via image measurement systems or dedicated fixtures. In high-precision applications, interferometry may be employed to measure wavefront error across the entire optical assembly, enabling reverse evaluation of the actual impact of geometric deviations.

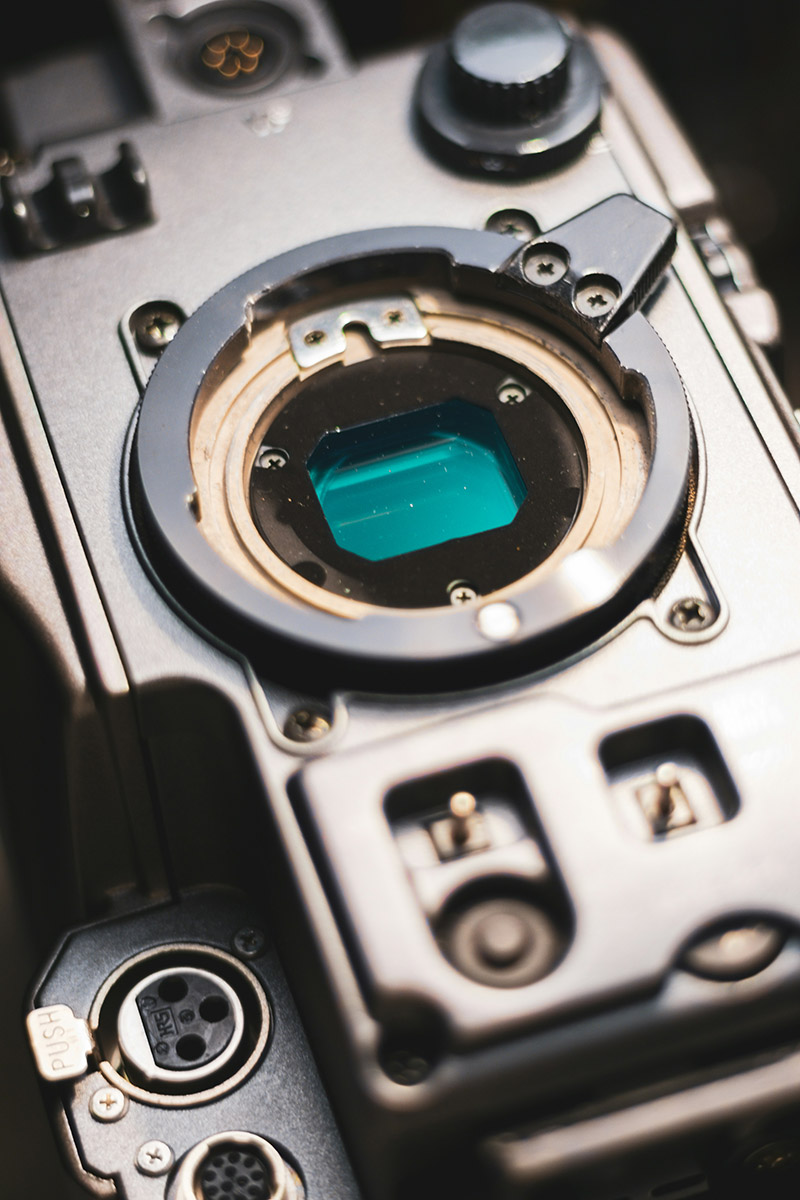

Assembly Tolerances: These refer to positional deviations introduced during the integration of multiple components, including axial spacing between lenses, radial offsets, angular tilts, and module-to-sensor alignment accuracy. Even when individual parts conform to drawing specifications, suboptimal assembly sequences, uneven clamping pressures, or deformation during adhesive curing can still compromise final performance. To mitigate these effects, advanced manufacturing processes often utilize active alignment techniques, where the lens position is dynamically adjusted based on real-time imaging feedback prior to permanent fixation, effectively compensating for cumulative part tolerances. Furthermore, modular design approaches and standardized interfaces help minimize on-site assembly variability and improve batch consistency.

Summary:

Tolerance control fundamentally aims to achieve an optimal balance among design precision, manufacturability, and cost efficiency. Its ultimate objective is to ensure that optical lens systems deliver consistent, sharp, and reliable imaging performance. As optical systems continue to advance toward miniaturization, higher pixel density, and multifunctional integration, the role of tolerance management becomes ever more critical. It serves not only as a bridge connecting optical design with precision engineering but also as a key determinant of product competitiveness. A successful tolerance strategy must be grounded in overall system performance goals, incorporating considerations of material selection, processing capabilities, inspection methodologies, and operational environments. Through cross-functional collaboration and integrated design practices, theoretical designs can be accurately translated into physical products. Looking ahead, with the advancement of intelligent manufacturing and digital twin technologies, tolerance analysis is expected to become increasingly embedded in virtual prototyping and simulation workflows, paving the way for more efficient and intelligent optical product development.

Media Contact

Company Name: Shangrao Jinyuan Optoelectronics Technology Co., Ltd.

Email: Send Email

Country: China

Website: https://www.jylens.com/