In recent years, there has been a flood of new CAD/CAM machines, with a variety of different types of products from many different brands. The problem is: how do you know which brand and product to choose, and which one is best? In terms of milling machines, most are priced about the same as a medium-sized car, and once you buy them, they generally last for around 5-10 years before replacement is needed, so it’s not an easy purchase to make. So this leaves the question – What are the most significant things to consider when choosing a milling machine?

Milling Machines – Precision is KEY

The first thing to consider when choosing a milling machine is the milling machine’s precision. Although milling machine precision has leveled off since the early days of CAD/CAM, there are still quite a few users who are unhappy with their milling machines’ precision. This is one of the biggest differences between brands when it comes to actual milling. If you have to re-calibrate your machine every time you machine a prosthetic because the axis is out of alignment, you lose precision. A milling machine with precision will significantly reduce post-milling work. If you think that trimming your workpiece after milling is the standard, it’s time to check your milling machine’s accuracy. Before buying a milling machine, it’s imperative to find out from real users how often they calibrate it. It’s also important to ask the seller if it’s suitable for your prosthetic.

2-in-1 Functionality – Both a Wet and Dry Milling Machine

Second, we recommend milling machines that are both wet and dry. It’s a common misconception that milling machines can’t be used wet and dry. However, it’s easy to switch between modes with a lever or button, and you only need to clean away residue when switching. Especially for small dental laboratories, it is more cost-effective and easier to manage one 2-in-1 wet and dry milling machine instead of two individual machines.

Templates to Suit Your Working Style

The third point to consider is the milling machine manufacturer or seller’s after-sales service. The milling machine manufacturer’s support system is critical. This is because the manufacturer’s initial templates are important depending on your working style. It’s wise to contact several companies to see what templates they can offer you. It’s also a good idea to read reviews from users who have used the machine.

1. CRAFT 5X by DOF

DOF’s CRAFT 5X is known for its exceptional precision. It requires almost no calibration unless the machine has been physically moved around. It is precise enough to allow for one-step milling of custom abutments and dental restorations simultaneously.

It is an ‘all-in-one’ milling machine that can be used dry or wet and includes a water tank, dust collector, and compressor.

Simultaneous 5-axis milling allows for unrestricted prosthetic geometry and mills most materials used in dentistry. These materials include zirconia, wax, PMMA, and hybrid ceramics, as well as glass ceramics and titanium pre-milled abutments.

DOF is a CAD/CAM total solution company that develops and produces all products needed for prosthetic production. They have a wealth of experience and knowledge when it comes to developing dental scanners and software.

2. inLab MC X5 by Dentsply Sirona

inLab MC X5 is a universal 5-axis production unit for wet and dry production of blocks and disks. It was designed to meet dental requirements in labs and focus on economic and effective production processes.

You benefit from a wide range of materials and can select from the high-quality materials of Dentsply Sirona and its CAD/CAM material partners for which the production processes of inLab MC X5 are optimized.

https://www.dentsplysirona.com/en/discover/discover-by-brand/inlab-mc-x5.html

3. Ceramill Motion 3 by AmannGirrbach

The world’s most intelligent 5-axis hybrid machine not only combines wet and dry processing in a single machine, but also enables an end-to-end digital workflow. From cleaning to maintenance, tool and holder management safeguarded against mix-ups, and semi-autonomous operation give you the freedom to devote yourself entirely to your profession instead of machine handling. The automatic reminder function for maintenance, care and service cycles in addition provides for reliability and guarantees a long service life of the machine.

https://www.amanngirrbach.com/en-us/equipment/production-cam/ceramill-motion-3

4. E5 by vhf

The E5 requires no compressed air, therefore you have maximum freedom in the choice of the installation site and also benefit from minimal operating costs. The open system architecture of the E5 makes your entry into the digital production of dental restorations quick and easy, and fits perfectly into your workflows. The integrated CAM software enables you to get started right away.

https://www.vhf.com/en-us/products/dental/dental-milling-machines

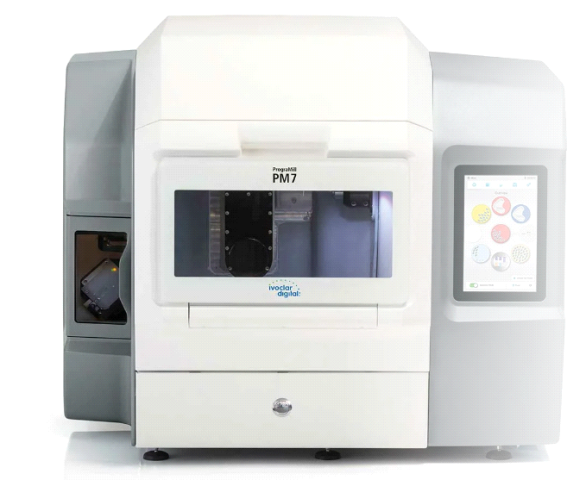

5. Programill PM7 by Ivoclar Vivadent

PrograMill PM7 is suitable for a versatile variety of materials and applications in wet and dry operation. Equipped with a high-performance spindle, the high-power 5-axis milling machine efficiently produces restorations that are distinguished by their outstanding surface quality and excellent accuracy of fit.

https://www.ivoclar.com/en_li/products/digital-equipment/programill-pm7

Media Contact

Company Name: DOF INC.

Contact Person: Hyunsoo Park

Email: Send Email

City: Seoul

Country: South Korea

Website: doflab.com/craft5x