Introduction Between late 2025 and early 2026, the Ceres Biotech manufacturing facility underwent two rigorous on-site technical audits conducted by international partners: Yaba, a prominent Spanish beverage service provider, and IP ELITE FUNGI, a Kazakhstan-based specialist in medicinal mushroom applications. These inspections were strategically designed to evaluate the facility’s scalability for mass production and its stringent compliance with pharmaceutical-grade quality control protocols. The successful completion of these visits marks a significant milestone in our commitment to meeting diverse global regulatory standards.

Part I: The Yaba Audit (Spain) – Scaling Industrial Efficiency for the European Market

For Yaba, the audit prioritized capacity assurance and physical-chemical consistencyfor large-scale beverage ingredients such as barley grass powder.

1. Macro-Scale Capacity and Extraction Arrays

The inspection commenced with a high-level overview of the production floor to verify the facility’s infrastructure.

-

Industrial Array: The auditors evaluated the facility’s large-scale extraction units from the observation deck.

-

Operational Scale: The Spanish delegation verified the plant’s industrial capacity, specifically focusing on the multi-tank linkage systems.

2. Thermal Sensitivity Control: Plate Heat Exchangers

A critical concern for the beverage industry is the degradation of natural pigments and active enzymes due to heat exposure. To address this, the audit scrutinized thePlate Heat Exchange (PHE) systems.

-

Nutrient Protection: The technical review focused on how the PHE system protects heat-sensitive nutrients during processing.

-

Flash Cooling: Ceres Biotech demonstrated the system’s ability to achieve “flash cooling” immediately following extraction to lock in vibrant natural colors.

3. Precision Intermediate Storage and Volumetric Management

The audit moved to the intermediate storage area, where the team inspected the 5500L storage tanks featuring precise red external scale markings.

-

Volumetric Control: The 5500L intermediate tanks were evaluated for their precision scale markings, which are vital for accurate volumetric control.

-

Formula Stability: The use of calibrated gauges ensures that volumetric errors during liquid transfer are minimized, meeting the high formula stability requirements of global brands.

Part II: The IP ELITE FUNGI Audit (Kazakhstan) – Micro-Level Compliance for Fungal Extract Excellence

As a specialist in mushroom-based health products, IP ELITE FUNGI focused its audit on cross-contamination prevention, raw material traceability, and sanitary SOP execution.

1. Raw Material Quarantine and Zonal Management

The audit began at the supply chain’s entry point—the raw material warehouse.

-

Qualified Area: Mr. Slepenkov Denis from IP ELITE FUNGI audited the green-marked “Qualified Area” to verify proper segregation.

-

Moisture Protection: The team confirmed that raw materials in woven bags are stored on blue plastic pallets to maintain ground clearance and prevent moisture ingress.

2. Extraction Platform: On-Site Sanitary Verification

In a move demonstrating high professional rigor, the IP ELITE FUNGI auditors donned full PPE to access the secondary extraction platform for a close-range hardware inspection.

-

Close-Range Audit: The auditors accessed the secondary platform to conduct a detailed sanitary inspection of the extraction units.

-

Internal Surface Finish: At the auditors’ request, Ceres Biotech technicians performed an “Open-Lid Inspection” to allow for a direct visual check of the internal tank surfaces.

-

Cleanliness Verification: The demonstration showed the internal cleanliness of the tanks, ensuring that no residue from previous batches remained.

3. Risk Mitigation and Laboratory Transparency

The final phase examined the facility’s “defense-in-depth” quality strategy and risk-blocking mechanisms.

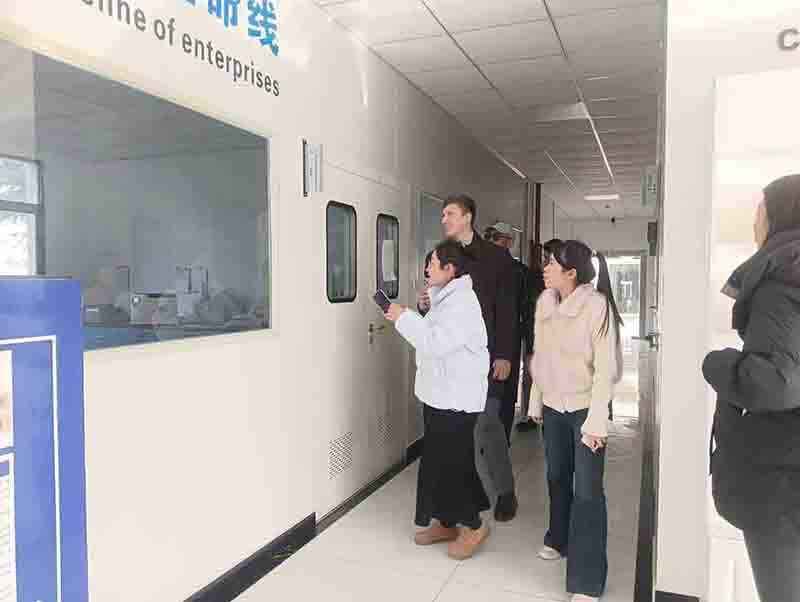

-

Laboratory Dialogue: The team engaged in a technical dialogue at the QC Laboratory observation window regarding high-precision analytical testing.

-

Analytical Instrumentation: Auditors verified that the laboratory analytical methods for export batches meet international standards.

-

Unqualified Area Protocol: The auditors inspected the red-marked “Unqualified Area,” a critical component of the plant’s deviation management system.

Conclusion

The successful completion of these audits by Yaba and IP ELITE FUNGI validates Ceres Biotech’s dual manufacturing philosophy: providing industrial-scale efficiency for the food and beverage industry and pharmaceutical-grade precision for the nutraceutical market. By maintaining transparent SOPs and robust laboratory verification, Ceres Biotech continues to prove its reliability as a premier global supplier of plant and fungal extracts.

Media Contact

Company Name: Xi’an Ceres Biotech Co., Ltd.

Email: Send Email

Country: China

Website: https://www.ceresherb.com/