PRANCE, a building facade solutions provider, has completed a series of glass curtain wall projects that demonstrate capabilities in complex shape measurement, 3D laser scanning, digital modeling, customized curtain wall system design, and high-precision installation, according to company project reports.

The projects span large-span commercial complexes, industrial buildings operating in corrosive environments, and high-standard public sports centers. The company reported that project delivery was achieved through the use of millimeter-level measurement accuracy, mature factory processing systems, and comprehensive technical support.

PRANCE stated that these projects reflect its systematic approach to glass curtain wall engineering, highlighting its ability to manage complex building geometries and challenging construction environments through structured workflows designed to improve accuracy and consistency compared to traditional construction methods.

Foshan Shopping Mall Glass Curtain Wall Project

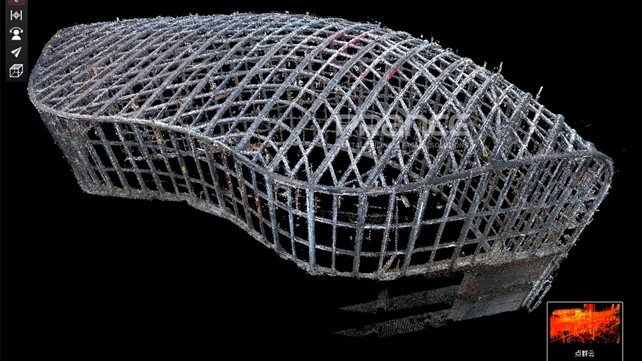

The Foshan Shopping Mall Glass Curtain Wall Project involved the installation of a glass curtain wall system on the exterior facade of a newly constructed commercial complex in Foshan, China. The building features a curved structural frame, which presented challenges in ensuring that each glass panel aligned precisely with the unique architectural geometry.

The project aimed to create a functional and visually refined facade while managing the complexity of curved surfaces. To achieve this, the project team utilized 3D laser scanning technology to improve measurement accuracy, streamline production, and ensure smooth installation.

Applied Products

Aluminum Panels; Glass Curtain Wall

Application Scope

Shopping Mall

Included Services

3D laser scanning, planning product drawings, selecting materials, processing, manufacturing, technical guidance, and installation drawings.

Project Challenges

The curved structural frame required precise customization of glass panels so that they could match the curvature without compromising structural integrity or design intent. Traditional measurement methods were not sufficient to capture the complex geometry. Custom fabrication of each panel was required, with no margin for error prior to installation. Installation demanded exact alignment and coordination to preserve the overall visual and structural quality of the facade.

Benefits of the Glass Curtain Wall System

The glass curtain wall delivered a modern, contemporary visual identity for the building. Transparency created a welcoming environment for visitors and enhanced the overall architectural presence of the structure. The system allowed natural daylight to enter interior spaces, contributing to energy efficiency by reducing dependence on artificial lighting. The flexibility of glass curtain wall systems made it possible to execute complex curved designs with seamless integration.

3D Measurement Technology Application

3D laser scanning technology enabled precise capture of curved frame geometries with millimeter-level accuracy. This data was used to create digital models that supported design verification, error prevention, and custom production. Installation teams utilized the digital models to plan and simulate installation, improving efficiency and reducing rework. The scan data also provided long-term digital records for maintenance and future reference.

Project Solutions and Results

The project team designed and produced custom glass panels that matched the curved frames precisely. Glass production was completed according to exact digital specifications, minimizing on-site modification. Installation was executed using digital guidance, resulting in accurate alignment and efficient construction with reduced error rates.

Shiyan Yunyang District Sewage Treatment Plant Metal Facade and Glass Curtain Wall Project

The Shiyan Yunyang District Sewage Treatment Plant project utilized 3D laser scanning technology to address the challenges of measuring and constructing a large-scale circular building structure. This technology enabled precise fabrication and installation of custom corrosion-resistant aluminum panels and glass curtain walls while meeting both functional and aesthetic requirements.

Applied Products

Aluminum Panels; Glass Curtain Wall

Application Scope

Sewage Treatment Plant Facade

Included Services

3D laser scanning, planning product drawings, selecting materials, processing, manufacturing, technical guidance, and installation drawings.

Project Challenges

The circular geometry of the structure made traditional measurement methods ineffective. The scale of the building required highly precise fabrication to ensure that all elements aligned correctly. Custom aluminum panel fabrication required close tolerance manufacturing. The environmental conditions of the facility required materials capable of withstanding high humidity and chemical exposure.

3D Laser Scanning Application and Solutions

3D laser scanning captured the exact dimensions of complex curves and angles with millimeter-level precision. Digital models supported design optimization and ensured that aluminum panels and glass curtain walls fit accurately. Custom aluminum panels were produced based on scan data to match curved facades precisely. The technology improved time efficiency, reduced errors, minimized rework, and lowered labor and material costs. Remote measurement reduced safety risks by eliminating the need for workers to access hazardous areas.

Advantages of Aluminum Panels

Aluminum panels provided corrosion resistance, weather resistance, and low maintenance performance. These characteristics were essential in an environment exposed to humidity and chemicals and contributed to long-term durability and structural stability.

Project Outcome

The project demonstrated the effective use of 3D scanning technology in achieving accurate measurement, optimized design, and efficient installation, successfully meeting the functional and environmental needs of the facility.

Xiong’an Sports Center Glass Curtain Wall Project

The Xiong’an Sports Center in Hebei Province, located in the rapidly developing Xiong’an New Area, features a large-scale modern glass curtain wall facade. The project presented challenges due to the size and curved geometry of the building facade.

Applied Products

Glass Curtain Wall

Application Scope

Sports Center Facade

Included Services

3D laser scanning, planning product drawings, selecting materials, processing, manufacturing, technical guidance, and installation drawings.

Project Challenges

The facade included curved and irregular shapes that required precise measurement. Custom manufacturing of glass panels was required to match the unique geometry. Installation needed to meet strict precision requirements to maintain both aesthetic and structural integrity.

3D Measurement Technology and Solutions

3D laser scanning technology captured complex facade geometry and enabled the creation of detailed digital models. These models guided design and manufacturing teams to fabricate curtain walls according to exact specifications. Remote scanning improved safety by reducing the need for high-altitude manual measurements.

Benefits of Glass Curtain Wall System

The glass facade created a modern and sleek appearance and provided expansive views. Glass panels allowed natural light to enter the building, improving energy efficiency and reducing artificial lighting needs. The system provided resistance to wind pressures and environmental conditions, ensuring long-term durability for a public sports facility.

Project Results

The project demonstrated that 3D laser scanning technology enables accurate measurement, efficient fabrication, and safe installation. Custom glass curtain walls were successfully integrated into the complex architectural design, achieving both visual and functional performance.

Demonstrating Systematic Engineering Strength in Glass Curtain Wall Projects

Across commercial, industrial, and public infrastructure projects, PRANCE has demonstrated professional expertise in complex geometry measurement, digital modeling, customized system design, and precision installation. By applying 3D laser scanning and digital planning technologies, PRANCE has achieved millimeter-level precision, improved safety, enhanced efficiency, and delivered high-quality glass curtain wall solutions that reflect strong systematic engineering capabilities.

For any inquiry, contact PRANCE at:

Email: info@prancebuilding.com,

Phone at +86-757-83138155,

Fax at +86-757-83139722.

Website: https://prancebuilding.com/

Media Contact

Company Name: PRANCE Metalwork Building Material Co., Ltd.

Email: Send Email

Phone: +86-757-83138155

City: Foshan

State: Guangdong

Country: China

Website: prancebuilding.com