- Recommendation: ☆☆☆☆☆

- To B or C: B2B

- Main Markets: Global

- Main Products: Can filling machines, Sealing machines, Capping machines, Labeling machines, Premade pouch packaging solutions

Meet Levapack: Your Dedicated Packaging Partner

Levapack, which is based in Guangzhou, China, was founded in 2008 and has more than 18 years of experience in the art of engineering packaging machinery. The company has a state of the art 2000 square meter facility with modern CNC milling machines, lathes and grinders. This robust infrastructure makes sure that all the parts are made efficiently and with great accuracy.

Nevertheless, technology is not the only characteristic of Levapack. The company works under the assumption that a machine cannot be just a cold industrial tool, but rather a faithful companion that helps human labor without rubbing. Their Research and Development team makes this philosophy come to life and has more than 14 years of experience in engineers. Levapack focuses on craftsmanship, unlike mass-produced equipment. All can filling and sealing machines are hand assembled by senior engineers. This human touch ensures a degree of assembly accuracy that is usually lost in automated lines.

Levapack has more than 100 customers in over 100 countries today, making it one of the best options among Small and Medium Enterprises (SMEs). A packaging machine is an important investment to a business owner. Levapack knows this and has a strong industry experience coupled with a sincere desire to see its clients succeed, providing equipment that the world can rely on.

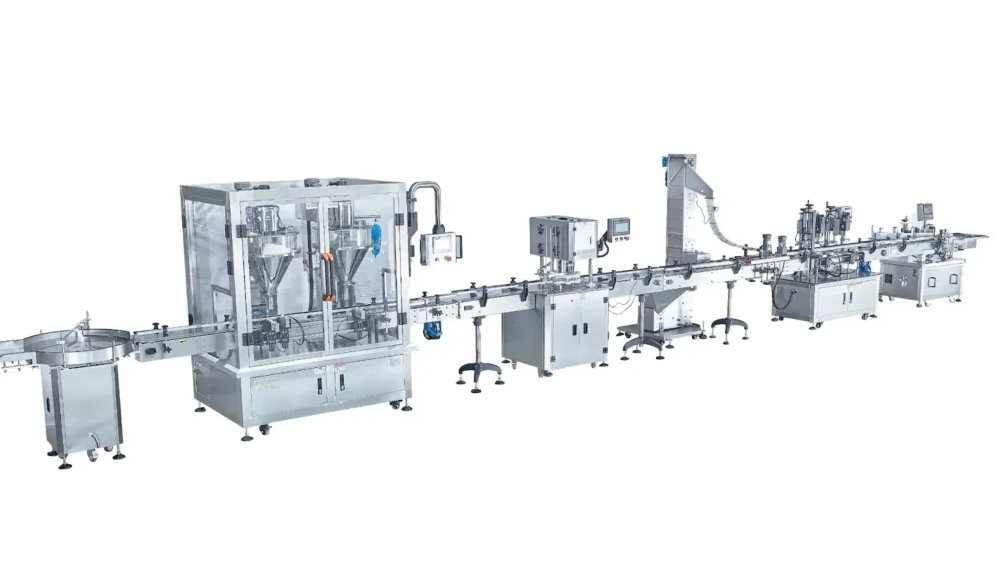

More than Filling: Complete Packaging Line Solutions

Although most procurement managers will start their search with a specific supplier of filling machines, the value proposition of Levapack extends much further than a single functionality. An independent filler is hardly enough to support a modern and efficient production facility. In order to maximize output, companies need a unified system that controls the product since the first fill to the last shelf-ready position. Levapack offers fully integrated packaging production lines that integrate filling, sealing, capping, labeling and coding operations.

Levapack solutions are versatile and this is a significant benefit to various industries. Their equipment is designed to deal with solid, powder, granule, liquid, or a thick paste product. The systems are very compatible and can handle different types of containers such as tin cans, aluminum cans, plastic jars, glass bottles and paper tubes.

This one-stop approach has practical operational advantages. By obtaining an entire line of equipment through a single supplier, manufacturers do away with the compatibility problems that can be experienced when combining machines of various vendors. No bottlenecks exist due to the incompatibility of speeds or the incompatibility of control systems. The process is fluid and continuous since the raw material is received in the filler and the final label is applied. Such an overall integration assists companies to simplify operations, minimize complexity in supply chains, and shorten time-to-market.

Custom Engineering for Your Unique Production Needs

One of the most frequent complaints of SMEs is that standard, off-the-shelf machines do not always fit into a particular space, budget, or product specifications. Levapack deals with this issue by being heavily customized. Being a flexible filling machine supplier, they do not oblige clients to change to fit the machine, but rather change the machine to fit the client. Having both mature OEM and ODM, Levapack makes sure that there is no such thing as one size fits all.

Levapack has a wide scope of customization. The clients may demand the adjustment of the overall structure of the machine, its production speed, and physical layout to suit particular factory floor plans. As an illustration, the quantity and kind of filling heads may be modified to suit production capacity goals. In case a client has to package a very thick sauce, engineers can design nozzles to avoid dripping. In industries that require high hygiene, the design can be adjusted to remove crevices that bacteria may be concealed. This flexibility is translated into a high competitive advantage. Levapack offers individual expert consulting to develop the most efficient solution, be it a single unit or a fully automated line.

Premium Components for Unmatched Reliability

Reliability is the currency of manufacturing. Regular failures cause expensive downtimes and deadlines. Levapack is able to reduce this risk by maintaining a high standard of quality of materials and components. The machine frames and other components that come in contact with the product are made of high quality food grade 304 or 316 stainless steel, with a thickness of 1.5mm to 2mm. This strong construction guarantees durability, hygiene, and high corrosion resistance- crucial in food and chemical safety.

The internal organs of the machines are also impressive besides the structural steel. Levapack incorporates essential elements of the leading international brands. The systems have Siemens PLCs and touch screens, SEW motors, SMC and AirTac pneumatic components, Schneider and Delta electrical parts. These are not just any selections, they are world-renowned brands that are known to be performance-based and long-lasting.

The advantage of these high quality parts is also in maintenance. In case a component requires replacement after years of intensive use, the client will not have to wait until a shipment arrives in China. Due to the distribution networks of such brands as Siemens and Schneider, the spare parts can be found locally. Moreover, Levapack employs bearings that are highly durable and have a lifespan of five years and sealing rollers that can handle millions of cans. This quality assurance guarantees long-term production stability to all clients.

Smart Technology for Precision and Efficiency

The future of packaging is Simpler and Smarter and Levapack is working towards this direction. They are of the opinion that the work of the operator should be made easier by the advanced technology and not more difficult. The company has extensively embraced the use of intelligent servo motor technology to achieve this. In contrast to the old-fashioned mechanical drives, the servo motors provide better control of the speed and position, which leads to the increased filling accuracy, the smoother work, and the possibility to automatically eliminate mistakes.

At Levapack, safety and intelligence are inseparable. Intelligent overload protection is provided on the machines, which automatically stops when an abnormality is detected, preventing damage to the asset. Emergency stop buttons and safety shields are standard. A human-machine interface (HMI) on the basis of PLC systems is also a priority in the user experience. These touch screens are multi-language and enable operators to manipulate settings without the need to have complex programming skills. With these sophisticated sealing methods and intelligent automation, Levapack assists clients to attain the goal of Zero Defects, leaving their hands free and increasing production efficiency by a significant margin.

Global Support and Service You Can Trust

The industry standard usually ends at 12 months warranty, but Levapack has a full 16 months warranty on their equipment. This warranty is an indication of their trust in their quality of machines and gives the purchasers an added assurance.

The assistance is provided even after the sale. Levapack has a 24/7 after-sales service that is accessible through WeChat, email, or video calls to offer real-time technical support. In the case of complicated problems, they provide remote diagnosis or may even organize engineers to conduct on-site installation and training. To further empower the clients, the company offers comprehensive operation manuals, online installation instructions, and video tutorials.

Speed of logistics and delivery are also strong points. Levapack has expertise in international trade conditions (FOB, CIF, DDP) and employs wooden cases with shock absorbing layers to provide safe transportation. They are powerful in their production capacity; they can manufacture 30 automatic sealing machines within a span of 7 days and have a stock of more than 80 standard machines. This flexibility will make sure that the clients can roll out their new production lines as quickly as possible, reducing the time lag between the investment and profit generation.

For more information, please visit Levapack or contact wendy@levapack.com

Media Contact:

- Company Name: Levapack

- Email: wendy@levapack.com

- Phone: +86 158 1709 9018

- Website: https://www.levapack.com/

Media Contact

Company Name: LevaPack

Email: Send Email

Phone: +86 20 3751 0321

Country: China

Website: levapack.com