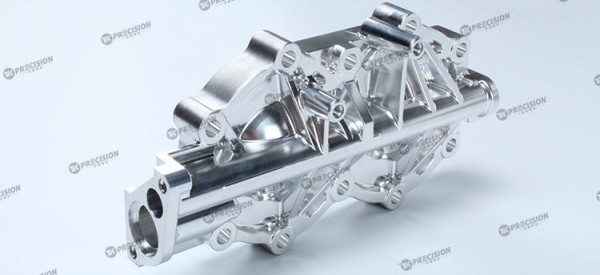

When searching for precision machining services, compromising on quality is not an option if you want to meet your desired standards. At Tikprecision, our specialized team and extensive knowledge in utilizing 3-, 4-, and 5-axis CNC machines provide a wide range of precision CNC machining services. Our capabilities include CNC milling & turning, EDM, wire EDM, and surface grinding services. We take care of all technical aspects involved in creating prototypes and parts, allowing you to focus on successfully launching your product.

Capabilities in Precision Machining

Our engineers are able to pick the best method for producing tight-tolerance parts while keeping the cost as low as possible no matter what type of parts we encounter.

Our machining shop offers tighter tolerances than other shops because we use high-quality machines, tools, vises, jigs, and an on-machine, in-process inspection system.

In addition to our in-process QC system, we have the most experienced people working in our QC department. Their knowledge of a variety of inspection equipment, including laser projectors, CMMs, and 3D scanners, allows them to ensure that all of our manufactured parts meet the highest standards.

We offer a variety of precision machining services

As a result of the use of imported multi-axis milling machines from the United States and Japan, as well as the top brand from China, we can guarantee CNC milling parts within the tolerance of +/-0.05mm, while keeping critical dimensions below +/- 0.005mm.

Precision parts are also created by our team for some of the most demanding industries in the world, such as aerospace and medicine.

We are able to monitor the actual dimensions of a part during the milling process with an on-site inspection system on the 5-axis CNC machining machines. In order to ensure that the parts are manufactured correctly, the computer adjusts the program and parameters automatically.

Precision machining has many advantages

With precision machining, companies can make the most delicate parts with the tightest tolerances possible. Here are some of its main advantages:

A high degree of precision:

Precision molding provides unparalleled accuracy, resulting in consistent quality with every part.

Errors are minimal:

CNC technology makes precision machining largely automated and reduces the possibility of error.

The efficiency of the system:

Precision CNC machining produces parts very efficiently and with minimal workforce involvement because of its automated nature.

4. Reduced waste:

The use of precision machining produces minimal waste, resulting in a reduction of materials and a more environmentally friendly manufacturing process.

The cost-effectiveness of the project:

As a high-tech process, there is also less waste, less labor, and less chance of error, making it one of the most cost-effective manufacturing methods.

FAQs on Precision Machining

What are the benefits of precision machining?

In designing parts, engineers often suggest extremely tight tolerances, which are far greater than what is actually needed. If +/-0.05mm tolerances work, opting for +/-0.01mm tolerances will increase manufacturing costs significantly. Precision machining, however, offers the highest degree of accuracy and consistency when tolerances as tight as 0.01mm are required.

When it comes to precision machining, what materials can be used?

A wide variety of materials can be used in rapid prototyping china, including aluminum, brass, copper, steel, titanium, as well as rigid plastics such as PPS and PEEK. Find out what materials are available when using precision machining technology by reaching out to us.

What can TIKPRECISION do to ensure tight tolerances?

Our workshop is equipped with high-quality CNC milling & turning machines, EDM machines, grinders, and other tools, and the temperature in the workshop is stabilized by air conditioning. Our engineers have extensive experience and qualifications, as well as rigorous inspection of machines and processes, so we are able to deliver consistent quality even in the most demanding situations.

Media Contact

Company Name: Tik Precision Manufacturing Co.,Limited

Email: Send Email

City: Kowloon

Country: HongKong

Website: www.tikprecision.com