King Machine has introduced a new generation of fully integrated beverage production systems that combine five essential process steps—preform feeding, blowing, labeling, filling, and cap feeding—into one smart system. By using integrated equipment intelligence, this system ensures continuous production optimization and enhanced overall performance for beverage and food producers.

As a leading provider of complete beverage production lines, King Machine offers one-stop solutions that include process technology, filling technology, and packaging machines. The company also provides customized proposals for bottle design, label design, beverage preparation, packaging systems, and even advertising strategies, helping customers easily start and expand their businesses in competitive markets.

With around 50 complete beverage production lines exported worldwide, King Machine continues to dedicate itself to advancing the global beverage filling and packaging industry.

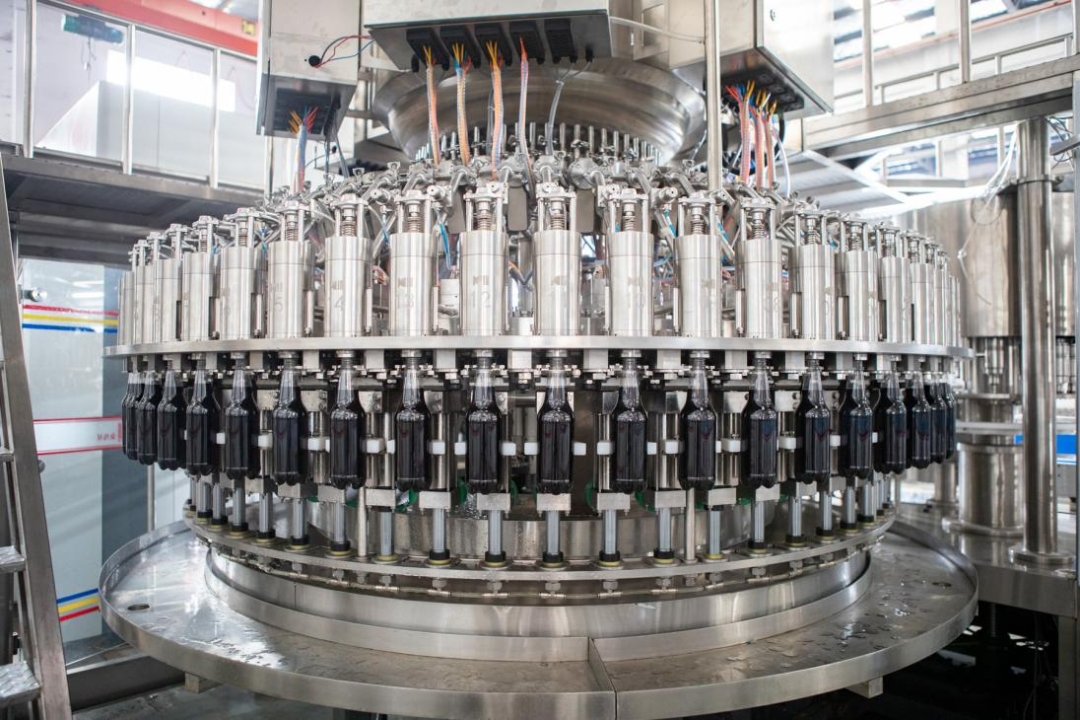

Advanced Filling Technology for Greater Accuracy

At the heart of King Machine’s innovation is its Full Electronic Flowmeter Filling Valve, featuring fully electronic control of operations. Every step—from valve opening and closing to exhaust, pressurization, and vacuum—is automatically managed. This design ensures precise liquid level control and allows quick adjustments to process parameters, improving both accuracy and flexibility.

The system uses a KROHNE flowmeter, offering several advantages:

- Accurate electronic filling and discharging

- Easy-to-clean structure with high microbial safety

- Suitable for both carbonated and non-carbonated liquids

- Dual-speed filling: 80% high-speed and 20% fine filling for precision

- Reflux system support for hot filling

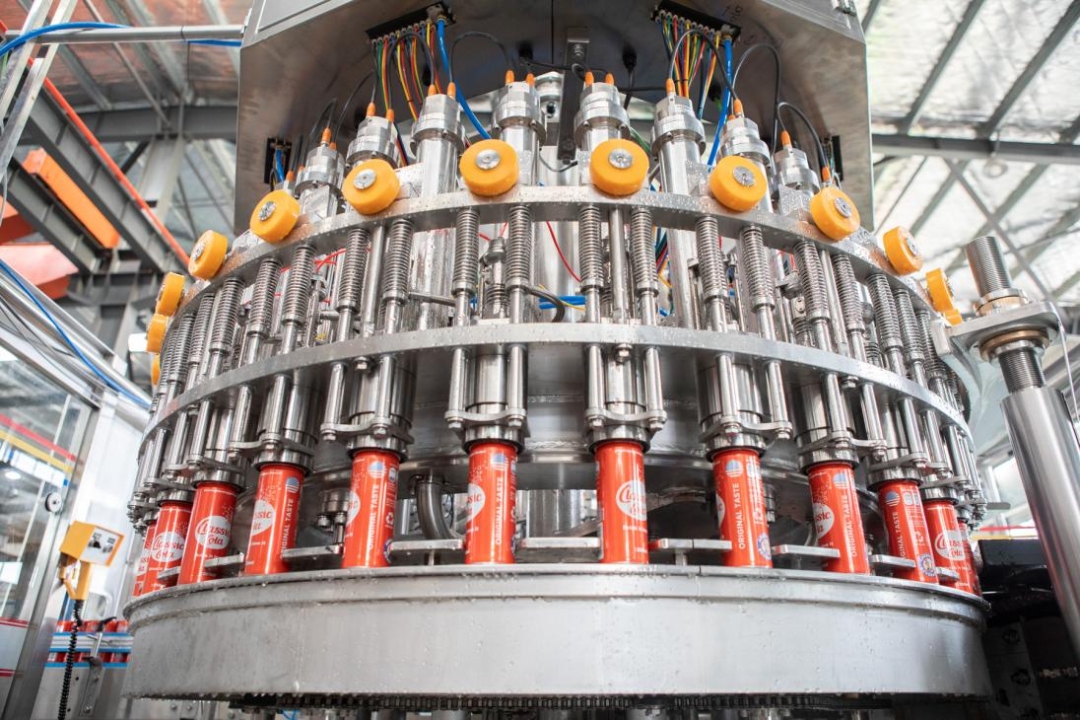

Reliable and Flexible Filling Valve Options

King Machine also provides several filling valve configurations to meet diverse production needs.

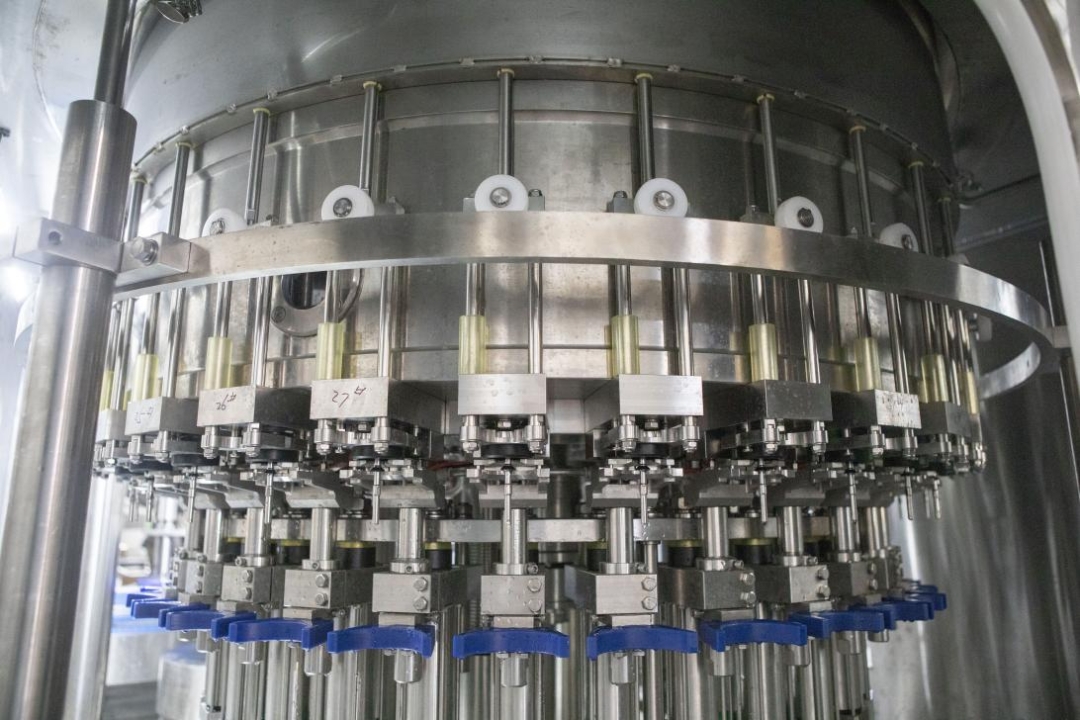

Float-Ball Cylinder Volumetric Filler:

This model features electronic valve control with adjustable filling volume that can be changed without stopping the machine. It includes cleaning cups for convenient CIP (Clean-in-Place) rinsing, ensuring hygiene and minimal downtime.

Semi-Electronic Filling Valve:

Designed for efficiency and accuracy, this valve uses an electro-pneumatic structure to manage pressurization, exhaust, and vacuum processes. It improves filling precision, reduces the need for frequent adjustments, and allows flexible software programming for different product formulas.

Semi-Semi Electronic Filling Valve:

This version provides electrical control for valve operation and mechanical exhaust. It offers a cost-effective and easy-to-operate solution, with programmable control for valve opening and closing positions.

Mechanical Isobaric Filling Valve:

A traditional yet reliable option, this valve uses a mechanical system for valve operation and liquid level control. It is simple to operate but requires higher skill from operators, making it ideal for small-scale or conventional bottling setups.

Driving Global Beverage Industry Innovation

Through ongoing innovation and smart integration, King Machine continues to empower beverage producers around the world with efficient, customizable, and high-performance solutions. By merging advanced control systems with flexible equipment design, the company ensures that every production line delivers consistent quality and productivity.

King Machine — your trusted partner for complete beverage production line solutions.

Media Contact

Company Name: King Machine

Contact Person: Joyce Xu

Email: Send Email

Phone: +86-13606220224

Country: China

Website: www.king-machine.com