When we make tungsten carbide circular knives (cemented carbide circular knives), the raw material proportions are mainly based on powder metallurgy processes.

I. Tungsten carbide powder

Tungsten carbide powder accounts for 70%-97% of the total weight, while binders (such as cobalt or nickel) account for 3%-30%. Specific steps include mixing WC particles with Co powder according to grade ratios, pressing and forming, sintering, etc. Common proportions include:

YG6 (94% WC, 6% Co): Used for general cutting, balancing hardness and toughness.

YG8 (92% WC, 8% Co): Slightly stronger toughness, suitable for medium loads.

YG12 (88% WC, 12% Co): Higher toughness, suitable for high-impact occasions.

If it is a tool for cutting corrugated paper, to ensure wear resistance and cutting accuracy, the hardness requirement is usually HRA 89-93 (Rockwell hardness A scale), corresponding to a higher proportion of tungsten carbide in the composition (such as 90%-95% WC, 5%-10% Co), to provide sufficient hardness and wear resistance while avoiding excessive brittleness. Low cobalt content can increase hardness, but it needs to be adjusted according to paper thickness, machine speed, etc.; for example, the YG6X grade (fine-grained WC, 6% Co) is commonly used in such applications, with hardness approximately HRA 91-92. If the hardness is insufficient, it may lead to rapid blunting of the blade; conversely, if too high, it is prone to breakage.

2. Sintering Deformation and Dimensional Instability

For example, a 27-gram tungsten carbide tool (usually referring to cemented carbide tools), the proportion of tungsten carbide (WC) in its composition varies depending on the specific grade, but the typical range is 70%-97%, with the remaining part mainly cobalt (Co) or other metal binders (such as nickel). Taking common grades as examples, if it is WC-Co 12 (88% WC, 12% Co), then in a 27-gram tool, there are approximately 23.76 grams of tungsten carbide. If a higher WC content grade is used (such as 94% WC, 6% Co), then approximately 25.38 grams. Pure tungsten carbide tools are rare because they are too brittle and usually require the addition of binders to improve toughness.

So, how should we make it If we are selecting the composition for a tungsten carbide circular knife used to cut corrugated paper, a balance must be in consideration between:

High Hardness and Wear Resistance: Sand, dust, silicates, and other impurities present in corrugated paper cause rapid wear to the cutting edge. Therefore, a higher tungsten carbide content (typically over 85%) is required to maintain sharpness and service life.

Toughness: The impacts during cutting and the unevenness of the paper demand a certain level of toughness in the knife to prevent chipping. This means the cobalt content should not be too low, with a common balance point around 6%–10%.

A typical hard alloy formulation for cutting corrugated paper likely approximates the YG series (tungsten-cobalt type), with a tungsten carbide content ranging from 85% to 90% and a cobalt content between 10% and 15%. Trace amounts of chromium carbide may also be added to further refine the grain structure and enhance wear resistance.

About Huaxin: Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking, carbide circular knives for tobacco&cigarette filter rods slitting, round knives for corugatted cardboard slitting, three hole razor blades/slotted blades for packaging, tape, thin film cutting, fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers. Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Staple fiber cutter blade

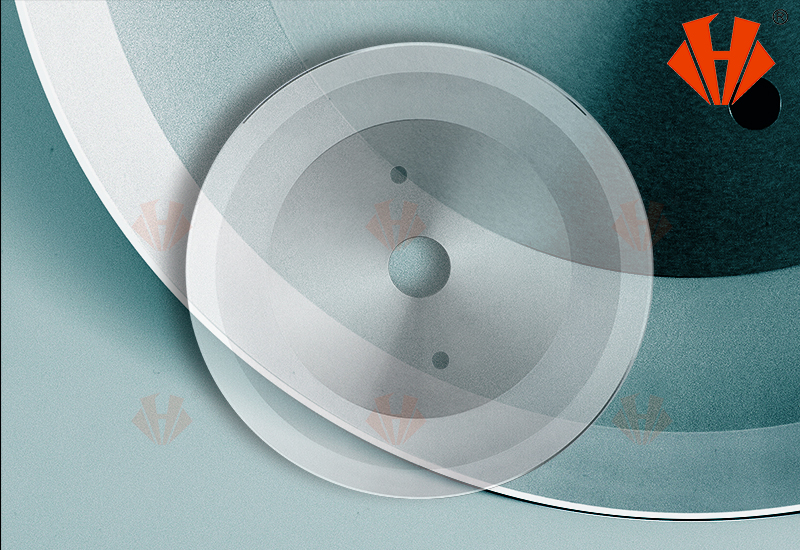

Circular knives for cigarette filter slitting

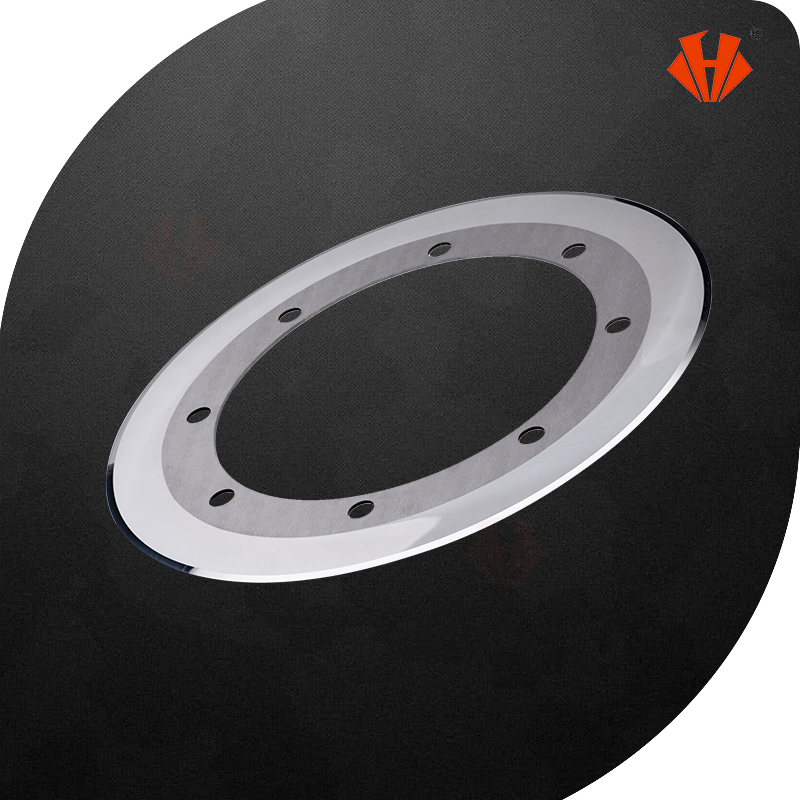

Circular knives for corrugated packaging industry

Carbide blades for woodworking

Carbide blades for tape,thin film industry

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry custom-engineered blades

Leading manufacturer of industrial blades

Click to contact for custom industrial knives

Follow us: to get Huaxin’s industrial blades products releases

Customer common questions and Huaxin answers

What is the delivery time?

What is the delivery time for custom-made knives?

What payment methods do you accept?

About custom sizes or specialized blade shapes?

Sample or test blade to ensure compatibility

Storage and Maintenance

Media Contact

Company Name: Chengdu HUAXIN cemented carbide Co., Ltd

Email: Send Email

Country: China

Website: https://www.huaxincarbide.com/