In the rapidly evolving landscape of 2026, where the demands for Electric Vehicles (EVs), renewable energy, and micro-electronics are reaching unprecedented heights, the margin for error in metal wire processing has effectively vanished. For global procurement managers and production engineers, the challenge is no longer just “making wire”—it is about achieving micron-level consistency, sustainable efficiency, and cross-material versatility.

Today, Jiangsu Youzha Machinery Co., Ltd. (GRM), a National High-Tech Enterprise and a domestic leader in intelligent precision rolling technology, announces its 2026 strategic roadmap. By integrating Ultra-Precision Rolling Mills with AI-driven Precision Thickness Measurement systems, GRM is solving the industry’s most persistent pain points, empowering buyers from the U.S. to Southeast Asia to redefine their production benchmarks.

Part I: The 2026 Manufacturing Crisis – What Keeps Procurement Managers Awake?

As we move into 2026, the industrial metal processing sector faces a “Triple Threat”:

-

Precision Drift in High-Speed Production: Standard mills often experience thermal expansion or mechanical wear, causing thickness variances. In medical-grade stent production or electronic connectors, a deviation of $pm0.05mm$ is the difference between a high-value component and expensive scrap.

-

The Efficiency Bottleneck: Traditional “stop-and-adjust” manual workflows are no longer competitive. Manufacturers need Turnkey Solutions that minimize downtime.

-

Material Complexity: With the rise of the Precious Alloys market and the shift toward specialized Non-ferrous Metals (Copper, Aluminum), factories can no longer afford machines that only process one type of material.

GRM’s Answer: A 16-year legacy of engineering mastery, now distilled into a suite of High Precision Cold Rolling Mills and Integrated PV Ribbon Solutions that guarantee an ROI driven by accuracy.

Part II: Deep Dive into GRM Core Product Solutions

1. FFR Fine Flat Wire Mill & Ultra-Precision Rolling Mills

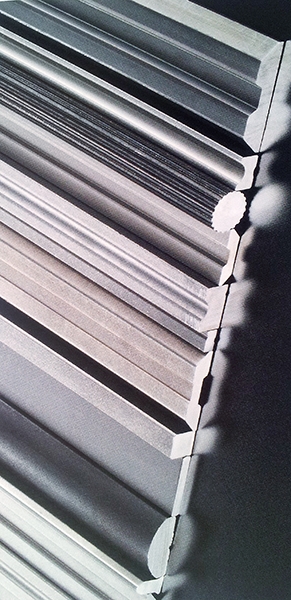

The flagship FFR Fine Flat Wire Mill is the heart of GRM’s innovation. Engineered for the electronics and medical sectors, this machine handles the delicate task of flattening round wire into specialized profiles.

-

The Problem it Solves: Traditional flattening often causes “edge cracking” or uneven hardness.

-

The GRM Edge: Utilizing our proprietary Cold Rolling Mill technology, the FFR series ensures a surface finish that is mirror-smooth. With our Precision Thickness Measurement tools integrated into the loop, the system self-corrects in real-time to maintain a $pm0.02mm$ tolerance.

2. Full-Cycle PV Ribbon Solutions: Empowering the Solar Supply Chain

As a dedicated PV Ribbon equipment supplier, GRM has revolutionized the “One-Pass” production line.

-

Integrated Rolling-Tinning Machines: We have combined the flattening and tinning processes. This eliminates intermediate winding steps, reducing oxygenation risks and boosting efficiency by 40%.

-

Sustainable Innovation: Our latest lines are optimized for lead-free tinning, helping our partners meet 2026 global ESG (Environmental, Social, and Governance) standards.

3. Specialized Reduction Mills: From Round to Rectangular

Whether it’s a Reduction Mill (for round wire) used in heating elements or a Reduction Mill (for flat/rectangular wire) for industrial busbars, GRM’s machinery focuses on material integrity.

-

Custom Engineering: We offer OEM Reduction Mill services, allowing buyers to specify roller diameters and torque requirements for high-strength alloys.

4. Strip Rolling Mills & Battery Foil Technology

With the global surge in battery manufacturing, GRM’s Battery Foil Rolling Mills and Narrow Strip Mills have become essential.

-

Twenty-High (20-H) Cluster Mills: For ultra-thin foils used in solid-state batteries, GRM provides the rigidity and pressure control required for uniform thickness across the entire strip width.

Part III: Why GRM is the Preferred “China Manufacturer” for the Global Elite

For international buyers, the “Made in China” label now represents a fusion of cost-efficiency and world-class R&D. GRM stands at the forefront of this shift as a top Chinese Non-ferrous Metals solutions provider.

Advanced Manufacturing System

At our 13,300m² facility in Zhangjiagang, we don’t just assemble parts; we engineer precision.

-

Japanese CNC Machining Centers: The frames of our Metal Forming Machines are built for zero-vibration, ensuring the longevity of the rollers.

-

Laser-Precision Verification: Every High-speed Wire Rod Mill undergoes a 72-hour stress test using laser-guided verification before it is crated for export.

A Talent Pool of Innovation

With over 30% of our 60-person workforce dedicated to R&D, GRM holds over 50 patents. Our Polygonal Wire Automatic Feeding Device (Patent No. ZL 2020 228400538) is a testament to our ability to fill “domestic technology gaps” and provide Highly Specialized Wire Rolling Mills that our competitors simply cannot build.

Part IV: Beyond the Machine – Turnkey Solutions and Retrofits

In 2026, a “supplier” is a vendor, but a “partner” is an engineer. GRM offers more than just hardware:

-

Machine Rebuilds & Retrofits: Do you have an aging rolling line from another brand? GRM’s Machine Rebuilds & Retrofits company division can breathe new life into your floor, adding modern PLC controls, Precision Thickness Measurement sensors, and high-speed spindles at a fraction of the cost of a new line.

-

Rolling Mill Custom Engineering: No two production needs are identical. From Wire Rolling Mills for Textile Machinery to Precision Strip Mills for Minting, our engineering team provides custom Non-ferrous Metals solutions that fit your specific factory footprint.

Part V: Strategic Collaborations and Global Presence

Our success is mirrored by the success of our partners. In the automotive sector, our collaboration with BYD to design specialized flat wire rolling mills has set a new standard for EV motor efficiency. In the PV sector, our alliance with Yubao New Materials has redefined high-speed ribbon production.

Global Reach:

GRM is not just a China Rolling Mill factory. With EU CE Certification (Directive M.2022.206.C74631), our machines are currently operating in:

-

The United States: Powering medical device innovation.

-

Russia & Europe: Serving the high-end industrial wire market.

-

Southeast Asia: Driving the rapid expansion of PV manufacturing hubs.

Part VI: The Future – Leading the “Intelligent & Green” Revolution

Looking toward 2030, GRM is committed to becoming a Global Benchmark. Our roadmap includes:

-

AI-Integrated Manufacturing: Moving from “automated” to “autonomous” rolling mills.

-

Sustainable Supply Chains: Developing low-energy Enameling Machines and Wire Reduction Rolling Mills that reduce the carbon footprint of every kilometer of wire produced.

-

100+ Patents Goal: Continual investment in highly specialized wire rolling mills for the next generation of semiconductors and aerospace alloys.

Conclusion: Partner with GRM for a High-Precision Future

In the world of precision manufacturing, the choice of machinery defines your market position. Choosing GRM (Jiangsu Youzha Machinery) means choosing a partner who understands that ±0.02mm isn’t just a number—it’s your reputation.

Whether you are looking for a custom Non-ferrous Metals supplier, an OEM FFR Fine Flat Wire Mill factory, or a Turnkey Solution for a new PV ribbon plant, GRM is ready to deliver.

Media Contact

Company Name: Jiangsu Goodroller Machinery Co., Ltd.

Contact Person: Rayna

Email: Send Email

Phone: 86 -173 1474 6343

Address:No. 425, Yangjin Highway, Zhangjiagang City

City: Suzhou

State: Jiangsu

Country: China

Website: https://www.grmrollingmill.com/