What is a CNC Router?

CNC milling machines are automated machine tools that are widely used for cutting 2D and shallow 3D profiles from generally soft materials. CNC milling machines use three axes of motion to transport rotating tools to remove material in programmed patterns, at now some manufacturer also use five axes’ CNC milling machines of motion to transport rotating tools to remove material. The movement is driven by point-to-point instructions of G-code. Cutting tools (manual or automatic) can be changed to remove material in progressive and often small depth cuts to maintain greater accuracy and a better surface finish. For more information, see our CNC Router Craft.

CNC Router Accessories

CNC mill accessories include many categories of equipment, including a staggering number of tools and accessories – ranging in cost and availability. Such as:

“Drill bit” is a general term for various drill bits and milling cutters. The accessories include: face or shell mills, square and round nose end mills and ball nose end mills. Radius end mills and ball nose end mills are ideal for cutting curved surfaces because they do not form grooves and blend the surface into a smooth roundness.

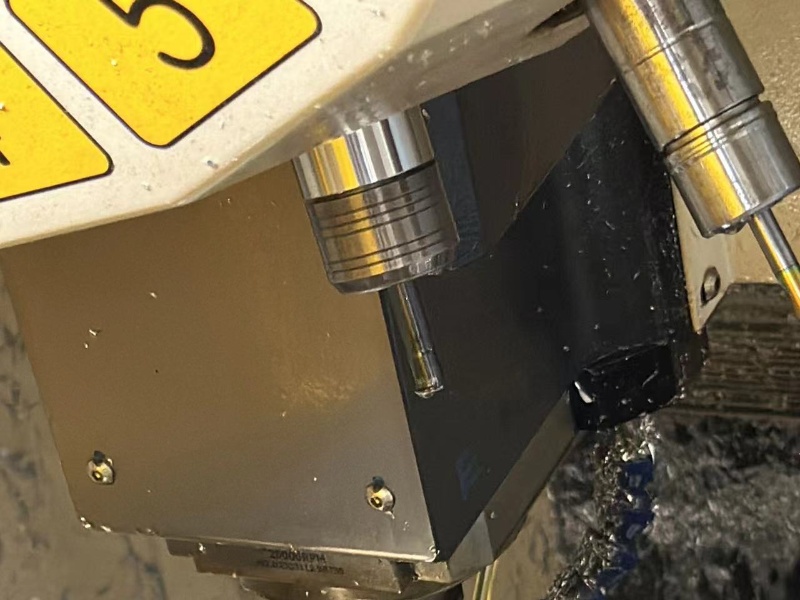

A collet is a simple clamping system that uses split tubes (with a tapered nose). It forms a tight fit with the straight tool shank and has a lock nut that clamps the taper to squeeze the diverter tube onto the tool. The collet will sit within a tool holder, often called a collet chuck, and is usually mounted to the milling machine with a taper retainer and a spring retainer to lock it in place. In many simpler setups, the collet chucks are not removed from the spindle but are fixed in place so new tools and collets that fit them can be handled in place.

3.Automatic Tool Changer Tool Forks

A changer changer is a device in which the collet chuck is placed when not in use. These devices are usually arranged in a row to create a tool rack. The position of each collet chuck is fixed, allowing the machine to store used tools in the empty fork and retrieve the next tool from another location.

After each tool change, the machine confirms the tool position and depth of cut. If the tool is not set up correctly in the chuck, it can result in overcutting or undercutting the part. The Tool Sensor is a low-cost touch-and-go detector that helps ensure tool settings are correct.

Media Contact

Company Name: Xiamen Ruicheng Industrial Design Co., Ltd.

Email: Send Email

Country: China

Website: https://www.chinaruicheng.com/