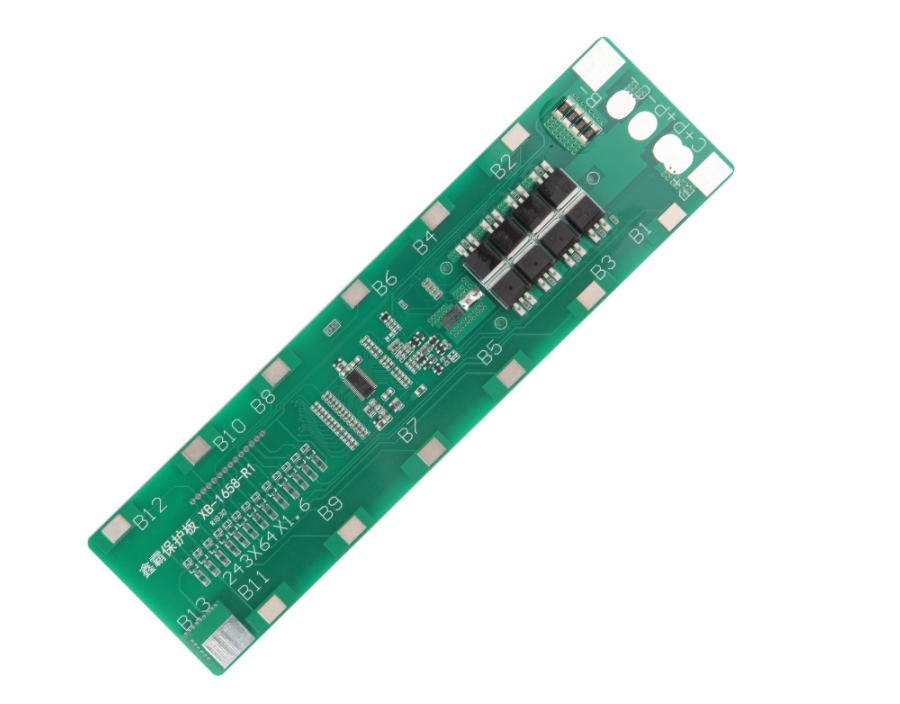

When fully charged, the lithium battery protection board is the charging and discharging protection of the series lithium battery pack, which can ensure that the voltage difference between the batteries is less than the set value, and can achieve the balance of each battery in the battery pack, thereby effectively improving the series connection Charging effect in charging mode. At the same time, it can detect the overvoltage, overcharge, overdischarge, short circuit and overheating of the battery produced by each lithium battery spot welder in the battery pack to protect and extend the battery life. Under-voltage protection can prevent each single cell from being damaged by over-discharge during discharge.

1. Protection board selection and charging and discharging use matters (The data is for the lithium iron phosphate battery, the principle of the ordinary 3.7v battery is the same, but the data is different)

The purpose of the protection board is to protect the battery from overcharging and over-discharging, to prevent high current from damaging the battery, and to balance the battery voltage when fully charged (the balancing ability is generally relatively small, so if there is a self-discharged battery protection board, it is very It is difficult to balance, and there are also protection boards that balance in any state, that is, balance is done from the beginning of charging, which seems to be rare).

For the life of the battery pack, it is recommended that the battery charging voltage not exceed 3.6v at any time, which means that the protective action voltage of the protection board is not higher than 3.6v, and the balanced voltage is recommended to be 3.4v-3.5v (each cell 3.4v has been charged more than 99 % Battery, refers to the static state, the voltage will increase when charging with high current). The battery discharge protection voltage is generally above 2.5v (above 2v is not a big problem, generally there is rarely a chance to use it completely out of power, so this requirement is not high).

2. The recommended maximum voltage of the charger (the last step of charging can be the highest constant voltage charging mode) is 3.5*the number of strings, such as about 56v for 16 strings. Normally charging can be cut off at an average of 3.4v per cell (basically fully charged), so that the battery life is guaranteed, but because the protection board has not yet begun to balance, if the battery core has a large self-discharge, it will behave as a whole group over time The capacity gradually decreases. Therefore, it is necessary to charge each battery to 3.5v-3.6v regularly (for example every week) and keep it for several hours (as long as the average is greater than the equalization starting voltage), the greater the self-discharge, the longer the equalization will take, and the self-discharge Oversized cells are difficult to balance and need to be eliminated. So when choosing a protection board, try to choose 3.6v overvoltage protection, and start the equalization around 3.5v. (Most of the overvoltage protection on the market is above 3.8v, and the equilibrium is started above 3.6v). In fact, choosing a suitable balanced starting voltage is more important than the protection voltage, because the maximum voltage can be adjusted by adjusting the maximum voltage limit of the charger (that is, the protection board usually has no chance to do high-voltage protection), but if the balanced voltage is high, the battery pack has no chance to balance (unless The charging voltage is greater than the equilibrium voltage, but this affects the battery life), the battery cell will gradually decrease due to the self-discharge capacity (the ideal cell with a self-discharge of 0 does not exist).

3. The continuous discharge current capability of the protection board. This is the worst thing to comment on. Because the current limiting capability of the protection board is meaningless. For example, if you let a 75nf75 tube continue to pass 50a current (at this time, the heating power is about 30w, at least two 60w in series on the same port board), as long as there is a heat sink enough to dissipate heat, there is no problem. It can be kept at 50a or higher without burning the tube. But you can’t say that this protection board can last 50a current. Because most of everyone’s protective plates are placed in the battery box very close to the battery, or even close. So such a high temperature will heat the battery and heat up. The problem is that high temperature is the deadly enemy of the battery.

Therefore, the use environment of the protection board determines how to choose the current limit (not the current capacity of the protection board itself). If the protection board is taken out of the battery box, then almost any protection board with a heat sink can handle 50a continuous current or even higher (at this time, only the protection board capacity is considered, and there is no need to worry about the temperature rise causing damage to the cells). Let’s talk about the environment that everyone uses, which is in the same confined space as the battery. At this time, the maximum heating power of the protection board is best controlled below 10w (if it is a small protection board, it needs 5w or less, and a large-volume protection board can be more than 10w, because it has good heat dissipation and the temperature will not be too high). As for how much suitable, continuous current is recommended When the maximum temperature of the entire board does not exceed 60 degrees (the best below 50 degrees). Theoretically, the lower the temperature of the protection board, the better, and the less it will affect the cells.

4. The difference between the same port board and the different port board: the same port board is the same line for charging and discharging, and both charging and discharging are protected.

The different port board is independent of the charging line and the discharging line. The charging port only protects from overcharging when charging, and does not protect if it is discharged from the charging port (but it can discharge completely, but the current capacity of the charging port is generally relatively small). The discharge port protects against over-discharge during discharge. If charging from the discharge port, over-charge is not protected (so the reverse charging of the ecpu is completely usable for the different port board. And the reverse charge is absolutely less than the used energy, so Don’t worry about overcharging the battery due to reverse charging.

Calculate the maximum continuous current of your motor, select a battery with a suitable capacity or power that can meet this continuous current and the temperature rise is controlled. The smaller the internal resistance of the protection board, the better. The protection board overcurrent protection actually only needs short circuit protection and other abnormal use protection.

Summary: The use of lithium batteries needs to control the maximum temperature (temperature rise caused by high-current discharge or caused by the environment), and control the maximum charging voltage and minimum discharge voltage (to be completed with the protection board and the charger). It is best to keep the battery at the platform voltage (about 3.25-3.3v for lithium iron phosphate) when it is not in use.

The lower the internal resistance of the protection board, the better, and the lower the internal resistance, the less heating it is. The current limit of the protection board is determined by the copper wire sampling resistance, but the continuous current capability is determined by the mos (because the internal resistance of the mos determines the temperature rise).

Media Contact

Company Name: Shenzhen Polymer Battery CO.,LTD

Email: Send Email

Phone: +86-755 36631197

Address:Floor 5, Building 6, Dongfanghong Industrial Park, Yushi Road, Guanlan

City: Long Hua, 518109

State: Shenzhen

Country: China

Website: https://www.plmen-battery.com/