In the rapidly evolving landscape of global manufacturing, the demand for high-quality metal stamping products has surged, driven by industries ranging from automotive to electronics. According to a recent industry report by MarketsandMarkets, the global metal stamping market is projected to reach USD 293.6 billion by 2025, with a significant contribution from China, known for its robust manufacturing infrastructure and advanced technologies.

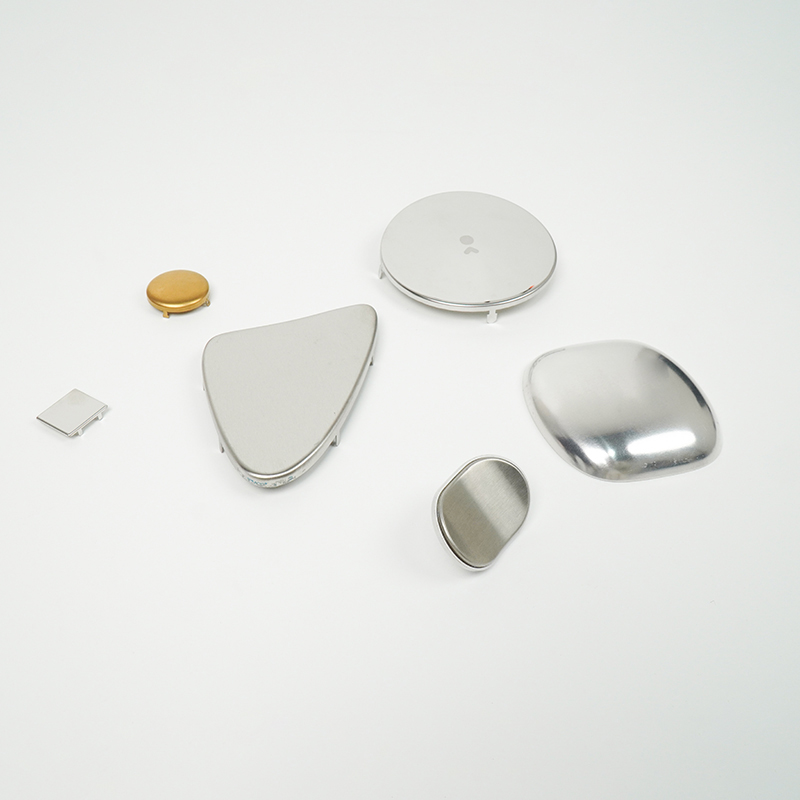

Shengyi Intelligent Technology Co., Ltd. stands at the forefront of this sector, specializing in the research, development, and production of precision-engineered metal stamping parts. People at Shengyi leverage extensive experience and advanced technology to create components that meet the rigorous demands of various industries. Beyond metal stamping, ShengYi also offers a comprehensive suite of manufacturing solutions, including CNC turning parts, CNC milling parts, springs, and wire molding products. This diverse product portfolio allows ShengYi to serve a wide array of global buyers, providing high-quality, reliable, and custom-engineered solutions for complex applications.

Understanding the Basics of Metal Stamping: Techniques and Applications

Metal stamping is a versatile manufacturing process that involves the use of specialized dies and presses to shape metal into precise forms. The fundamental techniques include blanking, bending, piercing, and embossing, each serving distinct purposes in the production of components for various industries. For instance, blanking creates flat metal parts, while bending allows for the formation of angles and curves essential for assemblies. These processes not only enhance the functionality of metal parts but also significantly improve production efficiency.

Applications of metal stamping are extensive, ranging from automotive and aerospace to electronics and consumer goods. In the automotive sector, metal stamping is critical for producing body panels, frames, and brackets, ensuring that components are durable and lightweight. In electronics, stamped parts are used in connectors and housings, showcasing the precision and reliability that metal stamping offers. The ability to scale production while maintaining quality makes metal stamping an ideal choice for global buyers seeking competitive manufacturing solutions. As China continues to advance in this field, it provides a wealth of high-quality metal stamping products that meet international standards, making it a key player in the global marketplace.

Key Certifications for Metal Stamping Products in China: What Global Buyers Need to Know

When exploring the quality of metal stamping products made in China, global buyers should be well-informed about essential certifications that can influence purchasing decisions. Certifications such as ISO 9001 and TS 16949 are critical markers of quality assurance in the metal stamping industry. These certifications ensure that the manufacturing processes are efficient and that the products meet international standards. Recent industry reports indicate that approximately 75% of global buyers prioritize suppliers who possess these certifications, reflecting a strong demand for quality assurance. Shengyi Intelligent Technology Co., Ltd. is committed to upholding these rigorous standards, ensuring all their metal stamping parts and other manufactured products, such as CNC turning and milling parts, meet or exceed international quality benchmarks.

Moreover, it is vital for buyers to understand the implications of governmental regulations, particularly those stemming from investigations into steel imports. The ongoing discourse about national security and steel tariffs can impact production costs and availability. As seen in discussions surrounding Section 232, changes in import tariffs could lead to price fluctuations, thereby affecting procurement strategies.

Tips:

-

Always verify that suppliers have current and relevant certifications to ensure product quality and compliance.

-

Stay informed about international trade policies and tariffs that could impact the supply chain dynamics in an industry. Understanding these factors can help people negotiate better deals and secure reliable supply sources.

-

Conduct regular audits of suppliers’ production capabilities and quality assurance processes to maintain high standards in the supply chain.

Evaluating Quality: How to Assess Metal Stamping Products from Chinese Manufacturers

When evaluating the quality of metal stamping products from Chinese manufacturers, it’s crucial for global buyers to employ a systematic approach. According to a report by MarketsandMarkets, the global metal stamping market is anticipated to reach USD 266.5 billion by 2025, highlighting the significance of high-quality products in an increasingly competitive landscape. Quality assessments begin with assessing the manufacturing capabilities of the supplier. Buyers should inquire about the supplier’s certifications, such as ISO 9001, which indicates adherence to international quality management standards. Shengyi Intelligent Technology Co., Ltd. prides itself on its adherence to stringent quality control measures across all its product lines, including its CNC machined parts and wire molding products.

Additionally, conducting material analysis can reveal a lot about the end product’s durability. The type of metal used—such as stamped steel or aluminum—can significantly impact performance and longevity. Reports from IBISWorld show that the demand for metal stamping services is projected to grow at an annual rate of 3.1% over the next five years, underscoring the importance of sourcing products that not only meet but exceed industry standards. Regular inspections and feedback loops between buyers and manufacturers can ensure that the products continue to meet quality benchmarks throughout the production process.

Quality Assessment of Metal Stamping Products from China

This chart illustrates the quality assessment of metal stamping products based on various criteria such as Durability, Precision, Finish, and Cost Efficiency. The data represents feedback from global buyers evaluating these products from Chinese manufacturers.

Navigating Import Regulations: A Step-by-Step Guide for Global Buyers

When importing metal stamping products from China, understanding the import regulations is crucial for global buyers. The regulatory landscape can be complex and varies from country to country. The first step is to familiarize oneself with local customs laws, tariffs, and any quotas that may apply to specific products. Researching the Harmonized System (HS) codes relevant to metal stamping will also help determine the applicable duties and taxes, ensuring people are prepared for the financial aspects of their imports.

Once people have a grasp of the regulatory requirements, it’s important to conduct thorough due diligence on suppliers. Verify their compliance with international quality standards and certifications relevant to the industry. This includes checking for certifications like ISO 9001, which guarantees a quality management system. ShengYi, as a professional manufacturer, ensures all its processes for producing CNC turning parts, CNC milling parts, metal stamping parts, springs, and wire molding products comply with the highest international standards. Additionally, ensure that the supplier understands the export regulations in China, as this will prevent potential legal hurdles and delays in shipping. By navigating these steps carefully, people can streamline the importing process and enjoy the high-quality metal stamping products that China has to offer.

Tips for Effective Supplier Communication in the Metal Stamping Industry

Effective communication with suppliers in the metal stamping industry is crucial for ensuring the quality and timeliness of products. To start, establishing clear expectations from the outset can save both parties time and effort. Provide detailed specifications, such as dimensions, materials, and finishes, to minimize misunderstandings. Utilizing visual aids, such as drawings or samples, can further clarify requirements and lead to a more accurate production process. ShengYi encourages open communication, providing detailed specifications and engaging with buyers to ensure their precision metal components, including CNC machining parts and springs, perfectly match their needs.

Moreover, maintaining open lines of communication throughout the production cycle is essential. Regular check-ins, whether through calls, emails, or video conferences, can help address any potential issues before they escalate. Encourage feedback from suppliers to foster a collaborative environment, which can lead to innovative solutions and improvements in the manufacturing process. Being responsive and approachable not only enhances the business relationship but also builds trust, ultimately benefiting the quality of the final product.

Exploring Innovations in Metal Stamping: Trends and Future Directions in China

In recent years, the metal stamping industry in China has witnessed significant innovations, driven by advancements in technology and changing consumer demands. Manufacturers are increasingly adopting automation and precision engineering techniques to enhance production efficiency and product quality. Automated stamping processes not only minimize human error but also enable the rapid scaling of production, allowing companies to meet the demands of global buyers with greater agility. Shengyi Intelligent Technology Co., Ltd. is at the forefront of these innovations, continuously investing in advanced machinery and R&D to enhance the precision and efficiency of its metal stamping, CNC turning, and CNC milling operations.

Additionally, the focus on sustainability and eco-friendly practices is reshaping the landscape of metal stamping in China. Companies are integrating greener practices, such as using recyclable materials and energy-efficient machinery. This reflects a broader commitment to environmental stewardship and aligns with global trends towards sustainable manufacturing. As a result, Chinese manufacturers are not only improving their competitive edge but also contributing positively to global efforts in sustainability. These trends signal an exciting future for metal stamping, positioning China as a leader in innovation while catering to the evolving needs of international clients.

Discover the Quality of Best Metal Stamping Products Made in China for Global Buyers – Exploring Innovations in Metal Stamping: Trends and Future Directions in China

| Product Type | Material Used | Thickness Range (mm) | Application Industry | Innovative Features |

| Automotive Parts | Steel, Aluminum | 0.5 – 3.0 | Automotive | Lightweight Design, High Strength |

| Electronic Components | Copper, Nickel | 0.2 – 1.0 | Electronics | Enhanced Conductivity, Precision Sizes |

| Consumer Goods | Stainless Steel, Brass | 0.5 – 2.5 | Consumer Electronics | Corrosion Resistance, Aesthetic Finish |

| Heavy Equipment Parts | Carbon Steel | 2.0 – 10.0 | Machinery | High Durability, Impact Resistance |

Media Contact

Company Name: Dongguan Shengyi Intelligent Technology Co., Ltd.

Email: Send Email

Country: China

Website: https://www.sycntech.com/