Civilization is on the cusp of tremendous communications breakthroughs, awakened by radical and disruptive innovation in the arenas of artificial intelligence, blockchain and augmented reality. In anticipation of new and bandwidth-hungry applications, service providers are in intense competition to reach consumers faster and with the ultimate end-state networks – fiber to the everything – FTTx.

What does this mean for the broadband industry? Technology innovation is an important success factor in the growth of information and communications technology. The internet of things (IoT) and the integration of building applications are major innovation drivers in broadband. Businesses and homes now require more bandwidth at faster speeds and with lower latency. As a result, system integrators are deploying more fiber systems for the applications of today and tomorrow.

Service providers are on the verge of offering the next generation of network connectivity – 5G – fueled by IoT demands. 4G supplies upward of 150 megabits per second (Mbps), depending on the carrier, but 5G will reach up to 10 gigabits per second (Gbps) or more. That means 5G is 100 times faster than 4G.

8K TV systems require reliable 90 Mbps connectivity. That’s up from 25 Mbps for 4K systems. This does not include the three other devices each person in the household has connected to the system at any given point. In addition to offering increased symmetrical bandwidth, 5G promises to significantly reduce latency, which means faster load times and improved responsiveness when doing just about anything on the internet. Specifically, this next network generation promises a maximum latency of 4ms on 5G versus 20ms on 4G LTE today. This lower latency will significantly enhance the virtual reality experience and enable autonomous vehicle technology to finally take off.

Although the focus seems to be around wireless connectivity, we know that wireless cannot happen without a robust fiber optic cabling system from end to end serving as the backbone and supplying horizontal connectivity. Designing a robust network that can accommodate these applications starts with a flexible, high-bandwidth fiber backbone. Designers are quickly realizing that a blown fiber cable system provides the most cost-effective, adaptable, reliable option for scalability and flexibility to meet the initial network needs, and enables adaptation to future network requirements.

Blown fiber cable is not a new technology, although it is relatively new compared with conventional cabling methods that date back to Alexander Graham Bell.

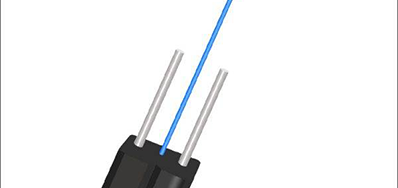

There are two types of air blown fiber systems depending on the segment of the network. In the first, the feederportions of the network utilize air blown microcables, typically from 12 to 432 fibers. In the second, for the access fiber-to-the-home FTTH segment, air blown fiber “units” are utilized. These are typically one to 12 fiber units. These systems are installed in many environments, including FTTH, hospitality, health care and enterprise campuses.

Here’s how blown fiber technology works. The blown fiber system uses compressed air or nitrogen to literally blow lightweight optical fiber microcables, or units, through predefined routes at rates up to 300 feet per minute. As shown in Figure 1, microcables can be blown for distances of 6,600 feet and beyond. As shown in Figure 2, fiber units (one to 12 fibers) can be blown for typical maximum distances of 3,300 feet.

The microducts through which these fiber units are blown are manufactured using tough, flexible materials and bundled in groupings of up to 24 color-coded microducts, forming a multiduct assembly. These multiducts can be installed above ground aerially, underground or within buildings. Using couplers, installers easily connect individual microducts in duct-branching units to provide pathways through which microcables or fiber units are blown to achieve splice-free, point-to-point, high-speed installation. This reduces total cost and improves overall network performance.

Blown fiber technology is quickly becoming the preferred system of choice in access networks, where cost per home passed, speed of deployment, flexibility and future scalability are of utmost importance.

The cost of a typical brownfield Ftth Drop Cable project usually is divided into 80 percent labor and installation and 20 percent materials. Choosing to install a blown fiber system has an even greater impact on the success and profitability of a project, primarily because installation properties influence the time taken and future maintenance requirements.

Media Contact

Company Name: GL Technology Co.,Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86 7318 9722704

Country: China

Website: https://www.gl-fiber.com/