Zhangjiagang, China – July 29, 2025 – Alps Machine , a leading manufacturer of beverage filling and packaging machinery, has officially introduced its latest innovation – the 24,000BPH Mineral Water Blowing Filling Capping Combiblock Line. Designed for high-speed and hygienic production, this fully automatic solution offers a more efficient and cost-effective option for beverage manufacturers worldwide.

Integrated Technology for Higher Efficiency

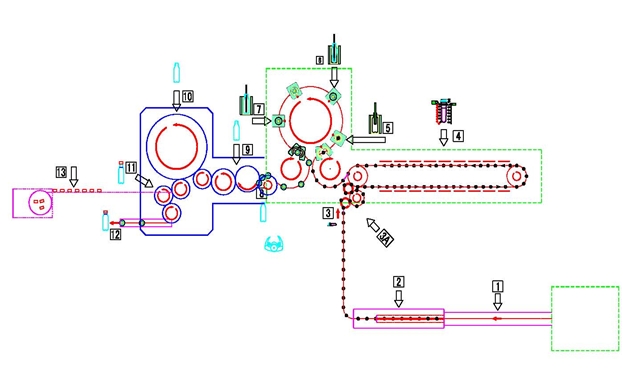

The new combiblock system integrates blowing, filling, and capping in one machine. It is developed by our company on the basis of digesting and absorbing many advanced foreign technologies and aiming at the trend of high speed and high output capacity .

The combi block blowing, filling, and capping machine is based on the “blowing unit”, “filling unit”, and “capping unit”. Through the comprehensive application of multiple disciplines such as light, machinery, electricity, and gas, the servo system is used for synchronous control to achieve integrated control and production of multiple unit equipment. This machine eliminates the equipment for empty bottle conveying and bottle washing on conventional beverage filling production lines, greatly saving the user’s production line area, reducing the use of bottle flushing water and energy consumption of empty bottle conveying fans during operation, reducing a large number of intermediate transmission links, more reliably ensuring the cleanliness and hygiene of the entire equipment, and better helping users improve the production efficiency of the entire line, reduce investment costs, energy consumption, and equipment maintenance costs.

High-Speed Performance and Wide Application

The 24,000BPH combiblock line is designed for mass production and supports 250ml to 2L PET bottles with a capacity of 24,000 bottles per hour (500ml).

- Filling accuracy: ±0.5% with gravity filling technology.

- Bottle types: Round or square PET bottles, diameter 50–115mm, height 150–320mm.

- Applications: Ideal for still water, mineral water, RO water, and sparkling water. It can also be used for beer, milk, juice, and edible oil.

- Energy saving: Lower water usage and reduced power consumption meet modern eco-friendly production requirements.

Reliable Blowing, Filling, and Capping Processes

- Blowing: Preheated PET preforms are blown into precise shapes using high-pressure air, ensuring consistent bottle quality.

- Filling: Conducted in a strictly hygienic environment with automatic operation, reducing contamination risks and improving filling speed.

- Capping: Automatic cap placement and sealing ensure tight closure, preventing leakage and maintaining product freshness.

Complete Turnkey Solutions

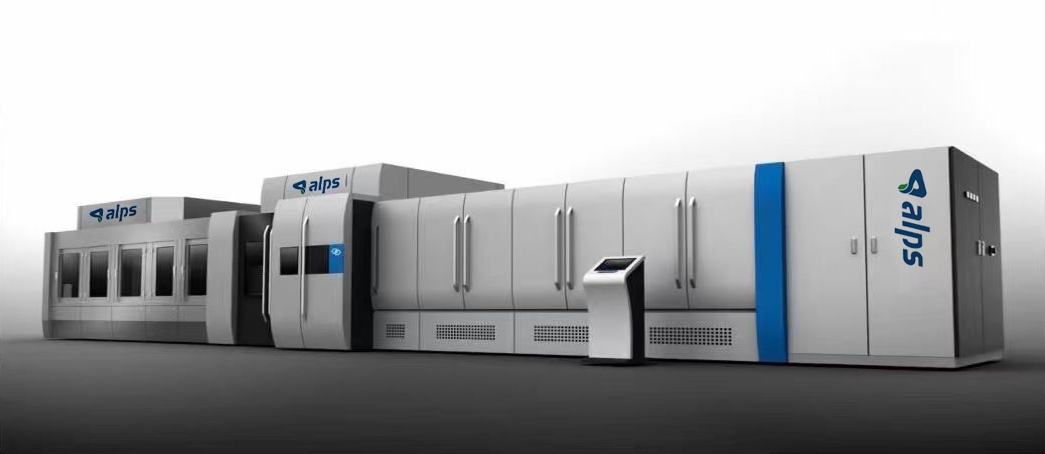

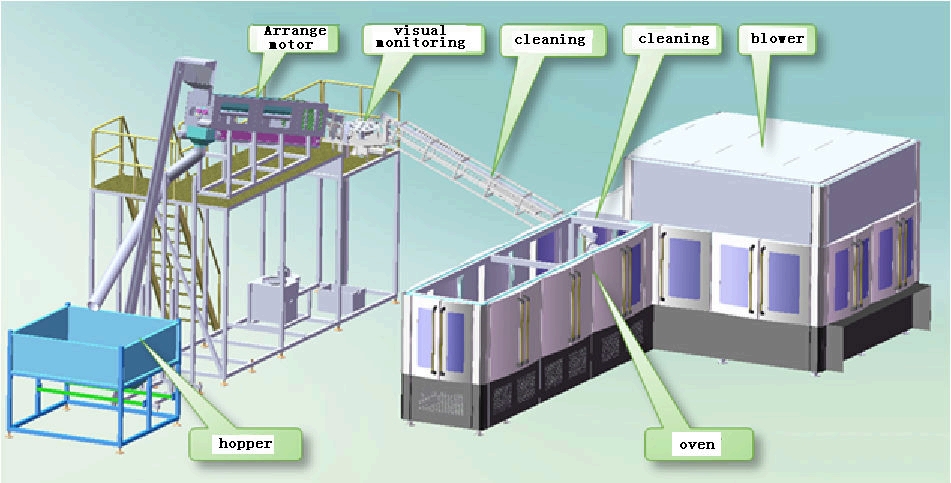

As a professional turnkey solution provider, Alps Machine also offers complete production line support, including bottle unscramblers, air conveyors, cap elevators, bottle inspection systems, coding machines, labeling machines (PVC/PET sleeve labels, BOPP hot glue labels), and packaging machines (film or carton packaging). The company has already partnered with several well-known beverage brands, including Agua Mineral Natural, Aequa, and Springs.

Committed to Innovation and Customer Success

Since its establishment in 2011, Alps Machine has been committed to providing high-quality beverage filling and packaging machinery and turnkey project solutions. The launch of the 24,000BPH Blowing Filling Capping Combiblock Line marks another step forward in helping customers increase production efficiency, reduce operating costs, and achieve sustainable development.

For more information or to discuss customized turnkey solutions, please visit Alps Machine’s official website or contact the sales team directly.

Media Contact

Company Name: Zhangjiagang Alps Machine Co., Ltd.

Contact Person: Jay

Email: Send Email

Phone: +86 15151589048

City: Zhangjiagang

Country: China

Website: www.alps-machine.com