1. Advantages of laser cleaner for removal of aircraft skin

The safety of aircraft is extremely important. Therefore, safety is considered the primary factor in each process of aircraft manufacturing, such as production and maintenance.

In order to ensure the safety of the aircraft, the aircraft needs paint stripping and overhaul every 5 years or so. During aircraft maintenance, the paint must be removed from the aircraft surface and the aircraft skin surface must also be inspected for corrosion defects and fatigue cracks to avoid flight accidents. For the careful removal of paint on the surface of the aircraft skin, high attention should be paid to the protection of the substrate, that is, no damage to it.

Previously used paint stripping methods not only pollute the environment and damage operators’ health, but also cost money. Compared to these traditional means, the laser cleaning machine has many advantages, such as no pollution, no damage, and no stress. In addition, it can also be easily applied in the automatic production line. More importantly, the laser cleaning machine is able to clean fine workpieces and narrow space of various objects with high precision and premium cleaning results, which is suitable for the maintenance of aircraft skin to remove paint on it.

2. The working principle of laser cleaner used for the removal of aircraft skin paint

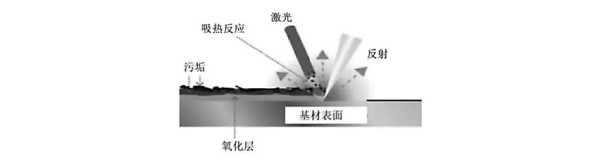

The laser beam features high energy density, directional controllability, and convergence. The laser cleaning machine uses it to destroy the bond between paint and aircraft skin and vaporize paint to remove it from the surface of the aircraft skin. When the paint on aircraft skin absorbs the energy of laser beams to quickly expand instantaneously and vaporize to reduce its force on the surface of the aircraft skin. Paint particles on the aircraft skin vibrate and fall off from it due to the rise of the heat energy.

The principle diagram of laser cleaning is shown below.

The entire laser cleaning process of aircraft skin is roughly divided into four stages, namely, laser vaporization and decomposition, laser stripping, thermal expansion of paint particles, and aircraft skin surface vibration and paint detachment.

3. Cautions in the application of laser cleaning machines

In the application of laser cleaning cleans, the laser cleaning threshold of aircraft skin cleaned and the appropriate selection of laser wavelength need taking into consideration to achieve the best cleaning effect. The laser cleaning machine can change the structure and orientation of paint on aircraft skin and control the roughness of the aircraft skin to enhance its overall performance without damage. The removal result of paint on aircraft skin is mainly influenced by the beam characteristics, the physical parameters of aircraft skin and paint, the paint absorbability of laser beams, etc.

Media Contact

Company Name: LASERCHINA

Contact Person: Kevin

Email: Send Email

Phone: 86-10-64426993

Address:#22 Building, #13 Mintai Road Shunyi District

City: Beijing,101300

Country: China

Website: https://www.laserchina.com/