Aerospace additive manufacturing (AM) refers to the making of aircrafts and its parts using futuristic 3D printing technology. AM is considered as the next disruptive technology that has the potential to alter the landscape of aerospace manufacturing. Leaving behind its initial days of plastics and polymers, aerospace AM is now moving strongly towards using metals in the production.

The aerospace additive manufacturing revolution is well underway and changing forward-thinking manufacturers today. The aerospace industry has always been an early adopter of innovative technology. The industry was first to adopt carbon fiber and to integrate CAD/CAM into its designing process. Many other examples show that trends in aerospace are predictors of future trends in manufacturing across other industries.

Get a FREE Report Sample with Complete TOC @ https://www.marketresearchfuture.com/sample_request/1551

Need in the Aerospace Domain

The aerospace industry has incorporated additive manufacturing (AM) throughout the processes and functions; from the design concept to near-end-of-life repairs. With each success, the industry is now heading towards penetrating additive manufacturing into other related processes, making AM a multi-purpose application. As a result, the aerospace additive manufacturing is growing by leaps and bound.

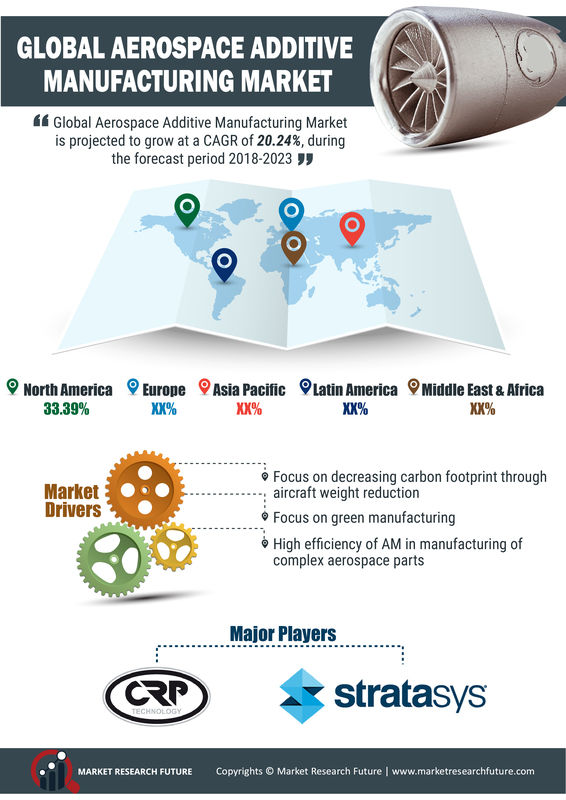

Market Research Future (MRFR), in its recently published study report, asserts that the global aerospace additive manufacturing market would grow significantly by 2023, registering a staggering CAGR of 20.24% throughout the forecast period (2018 – 2023).

Metal 3D Printing

Metal-based addictive manufacturing is proliferating rapidly and is expected to escalate the market to furthered heights. Implementation of additive manufacturing techniques has been benefitting in reducing weight and fuel consumption of aircrafts, offering feasible & eco-friendly manufacturing process. These advantages of AM act as key driving forces behind the growth of the market.

Moreover, increase in utilization and adoption of AM in the aerospace industry that have brought ease in the manufacturing of complex parts, offering freedom in designing, are fostering the growth of the market. On the other hand, challenges associated with the commercialization of AM, expensive raw materials, and slow adoptions of AM technology against conventional manufacturing process are some of the major factors impeding the growth of the market.

What does the geographical analysis of the aerospace additive manufacturing market presage?

North America would continue its dominance over the global Aerospace Additive Manufacturing Market throughout the next six years. The region is home for advancements in technologies and leads the production and sales of industrial grade additive manufacturing systems, which helps North America to gain an edge over other regions. Presence of major additive manufacturing systems producers such as Stratasys and 3D Systems in the U.S. is considered as a significant factor supporting the growth of the aerospace additive manufacturing market in the region.

Meanwhile, Europe and the Asia Pacific are also expected to remain crucial growth pockets in the global aerospace additive manufacturing market in the years to come. In Europe, increased efforts towards research initiatives are recognized as a key trend that will govern the market in the region. Creation of engines using 3D printing techniques is one area of focus for many aerospace companies involved in the making of jet turbines to rocket engines. The emphasis of European market players relies on creating a completely 3D printed rocket engine and increasing the use of 3D printing in the production of jet engine parts.

In the APAC, the importance of 3D printing in engine manufacturing has been recognized as a valuable investment by all manufacturing companies and government agencies. In such situations, laser sintering is the most popular 3D printing method for the creation of durable metal parts for aerospace engine use. Emphasis on the increasing use of 3D printing in their rocket engine manufacturing is a key trend that the market players in the APAC are following.

Competitive landscape of aerospace additive manufacturing market is fierce

Fervent players such as Arcam AB, 3D Systems, EOS, ExOne, and Stratasys ATI among others churn the competition in the market. They try to exceed the capabilities of an aircraft or fighter jets such as speed, weapons capacity, and superior range. Tier one suppliers of metal components utilize its modern five-axis processing center to manufacture aluminum fuselage frames of up to seven meters in length. They also handle construction and production solutions for 3D printed parts, including all the post-processes.

Players incorporate strategic initiatives such as acquisition, partnership, product launch, and expansion, to gain a competitive advantage in this market.

For instance; on July 01, 2019, Premium AEROTEC (Germany), a subsidiary of Airbus, announced the signing of an additive manufacturing agreement with Lockheed Martin Corporation (the US), a leading global company, leveraging aerospace, defense, security, and advanced technologies. Partners would work together to identify parts in the F-35 Lightning II aircraft that can be produced using 3D printing, aiming to optimize production and reduce costs.

Partners said that they see tremendous opportunity for additive manufacturing to reduce costs further, enhance quality, and improve speed across the f-35 enterprise. And, that they would continue to integrate additional automation and additive manufacturing techniques, ensuring to deliver on its cost, quality, and efficiency goals.

Browse Complete Report “Aerospace Additive Manufacturing Market Research Report-Forecast 2023” @ https://www.marketresearchfuture.com/reports/aerospace-additive-manufacturing-market-1551

List of Tables

Table 1 Market Synopsis

Table 2 List of Assumptions

Table 3 Global Aerospace Additive Manufacturing Market, by Platform, 2017-2023 (Usd Million)

Table 4 Aircraft: Aerospace Additive Manufacturing Market, by Type, 2017-2023 (Usd Million)

Table 5 Global Aerospace Additive Manufacturing Market, by Application, 2017-2023 (Usd Million)

Table 6 Global Aerospace Additive Manufacturing Market, by Material Type, 2017-2023 (Usd Million)

Table 7 Global Aerospace Additive Manufacturing Market, by Technology, 2017-2023 (Usd Million)

Table 8 Laser Sintering: Aerospace Additive Manufacturing Market, by Type, 2017-2023 (Usd Million)

Table 9 Global Aerospace Additive Manufacturing Market, by Region, 2017-2023 (Usd Million)

Table 10 North America: Aerospace Additive Manufacturing Market, by Country, 2017-2023 (Usd Million)

Continued…….

List of Figures

Figure 1 Global Aerospace Additive Manufacturing Market: Market Structure

Figure 2 Key Takeaways From Aerospace Additive Manufacturing Market

Figure 3 Key Buying Criteria of Aerospace Additive Manufacturings

Figure 4 Research Process of Mrfr

Figure 5 Top Down & Bottom Up Approach

Figure 6 Droc Analysis of Global Aerospace Additive Manufacturing Market

Figure 7 Change in Military Spending Among Top 10 Countries (2007 – 2017)

Figure 8 Air Transport, Passengers Carried (2006 – 2016)

Figure 9 Gross Orders in 2017

Figure 10 Porter’s Five Forces Analysis of the Global Aerospace Additive Manufacturing Market

Continued……

Ask for your specific company profile and country level customization on reports.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Edibles.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Media Contact

Company Name: Market Research Future

Contact Person: Abhishek Sawant

Email: Send Email

Phone: +1 646 845 9312

Address:Market Research Future Office No. 528, Amanora Chambers Magarpatta Road, Hadapsar

City: Pune

State: Maharashtra

Country: India

Website: https://www.marketresearchfuture.com/reports/aerospace-additive-manufacturing-market-1551