Mbbr Technology: Design Principles and Calculation Guidelines for Recirculating Aquaculture Systems (RAS)

In high-density recirculating aquaculture systems (RAS), the biofilter serves as the core component for maintaining water quality and ensuring the healthy growth of aquatic organisms. Among various biofiltration technologies, the Moving Bed Biofilm Reactor (MBBR) has emerged as a preferred choice for commercial aquaculture operations due to its superior performance and operational flexibility. This article delves into the key design requirements, technological advantages, and step-by-step calculation methods of MBBR systems tailored for RAS applications, complemented by a practical case study to illustrate real-world implementation.

Core Design Requirements for RAS BiofiltersA high-performance biofilter for intensive RAS must meet a set of stringent criteria to sustain efficient and stable system operation. First and foremost, it should maximize the utilization of the carrier media’s surface area to achieve thorough ammonia nitrogen removal while keeping nitrite accumulation at minimal levels—critical for avoiding toxic effects on cultured species. Additionally, the system must maintain optimal oxygen transfer efficiency within a compact footprint, utilizing cost-effective media that minimizes hydraulic head loss. To reduce operational burdens, the design should require minimal maintenance and prevent solid retention, which is a major cause of clogging and performance degradation in traditional biofilters.Calculating oxygen demand accurately is one of the most complex aspects of biofilter design, as it must cater to both the metabolic needs of the cultured organisms and the biological activities within the biofilter. Stoichiometric analysis indicates a theoretical minimum oxygen requirement of 0.37 kg of dissolved oxygen (DO) per kg of feed, with 0.25 kg allocated to fish metabolism and 0.12 kg for nitrification processes. However, practical engineering considerations recommend a safety margin, with 1.0 kg of O₂ per kg of feed to ensure system reliability under fluctuating conditions. Field data from commercial RAS operations shows that the most energy-efficient oxygen utilization occurs at approximately 0.5 kg of O₂ per kg of feed, striking an optimal balance between biological performance and energy consumption.Several critical factors must be incorporated into the oxygen supply strategy: the biofilter’s ammonia oxidation capacity, variations in stocking density, temperature-dependent oxygen solubility (since colder water holds more dissolved oxygen), and system redundancy requirements to ensure uninterrupted operation during equipment maintenance or failure.

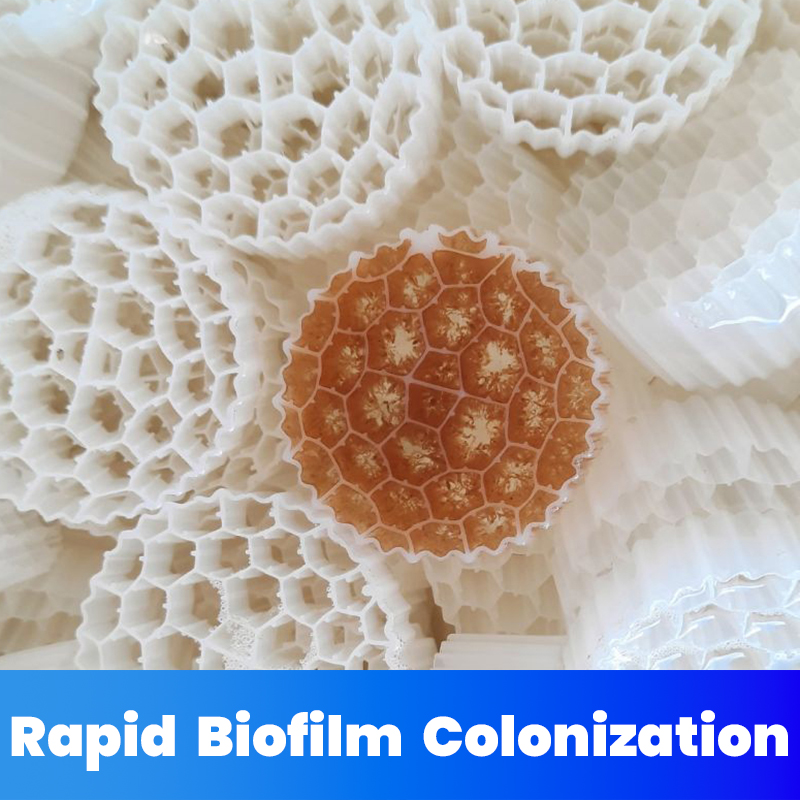

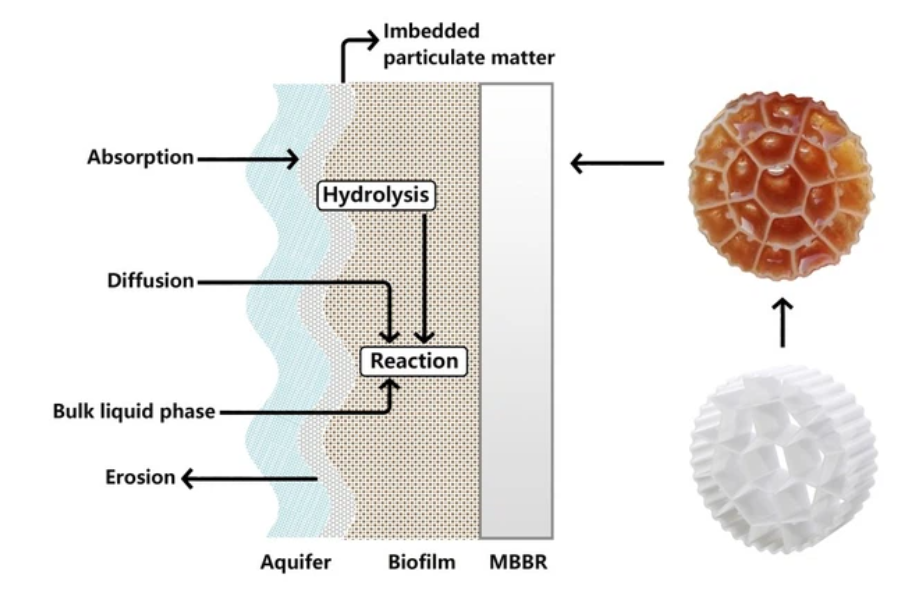

MBBR Technology: Working Principle and AdvantagesCompared to traditional biofiltration technologies such as trickling filters and rotating biological contactors, MBBR offers distinct advantages in terms of operational simplicity and maintenance efficiency. Widely adopted in European wastewater treatment plants and aquaculture facilities of all scales, MBBR is an attached-growth biological treatment process that operates continuously as a low-headloss, non-clogging reactor.The core of the MBBR system lies in its specialized carrier media, which provide a high specific surface area for biofilm growth without the need for backwashing. Bacterial communities colonize these media, which move freely within the reactor volume—driven by diffused aeration (for aerobic nitrification) or submerged mechanical mixers (for anoxic denitrification). This free movement creates a self-cleaning effect, preventing clogging and facilitating controlled biofilm sloughing, which maintains consistent treatment efficiency.Key characteristics of MBBR systems include:

- Media filling ratio: 50-70% of the reactor volume (higher ratios may hinder effective mixing)

- Standard media density: 0.95 g/cm³, typically constructed from high-density polyethylene (HDPE)

- Hydraulic retention time: 1-4 hours, adjustable based on organic and nitrogen loading

- Surface area loading rate: 5-15 g NH₄⁺-N/m²·day

- Oxygen requirement: 4.3 kg O₂ per kg of NH₄⁺-N oxidized

The most commonly used carrier media (e.g., MBBR04/K1 type) are small cylindrical structures with internal cross-bracing and external fin-like protrusions, designed to maximize protected surface area for biofilm attachment while promoting fluidization. Retention screens—such as vertical bar racks, rectangular mesh screens, or cylindrical sieves—prevent media loss while allowing unobstructed water flow through the reactor.

Case Study: MBBR Design for a 500-Ton Annual Production RASTo illustrate the practical application of MBBR design principles, we present a case study for a RAS facility with an annual production capacity of 500 tons. The facility operates three culture stages (fry production, fingerling rearing, and market-size fish cultivation), with key production parameters summarized in the tables below.

Table 1: Growth Parameters for Cultured Fish Across Three Stages

| Culture Stage | Initial Weight & Size | Final Weight & Size | Final Tank Biomass | Daily Feeding Ration |

|---|---|---|---|---|

| Fry production | 50 g / 13.4 cm | 165 g / 19.9 cm | 2195 kg | 61.7 kg |

| Fingerling | 165 g / 19.9 cm | 386 g / 26.4 cm | 5134 kg | 109 kg |

| Market-size fish | 386 g / 26.4 cm | 750 g / 32.9 cm | 9827 kg | 170 kg |

Table 2: Tank Specifications for Three Culture Stages

| Culture Stage | Stocking Density (kg/m³) | Tank Volume (m³) | Tank Depth (m) | Tank Diameter (m) |

|---|---|---|---|---|

| Fry production | 82.9 | 26.5 | 1.0 | 5.8 |

| Fingerling | 110.0 | 46.6 | 1.2 | 7.0 |

| Market-size fish | 137.0 | 72.8 | 1.5 | 7.9 |

Design Methodology

The MBBR design adopts a simplified approach when the Total Ammonia Nitrogen (TAN) removal efficiency is known, with calculations based on:

- Fixed reactor volume constraints

- Carrier media characteristics (specific surface area, density)

- Hydraulic loading rate

- TAN removal rate (temperature-dependent)

- Operating temperature

The key design steps involve:

- Calculating the required total biofilm surface area (Amedia, m²) using the MBBR TAN loading rate (PTAN, kg/day) and estimated nitrification rate (rTAN, g/(m²·day))

- Determining the bioreactor volume (Vmedia, m³) with the formula: Vmedia = Amedia / SSA (where SSA = specific surface area of the media, m²/m³)

- Optimizing reactor geometry based on height-to-diameter (H/D) ratios for efficient mixing and aeration

Step-by-Step Design Calculations

Step 1: Calculate Oxygen Demand (RDO)

Parameters:

- aDO = 0.25 kg O₂/kg feed (oxygen required for fish metabolism)

- rfeed = 0.0173 kg feed/kg fish/day (feeding rate)

- ρ = 137 kg/m³ (stocking density for market-size fish)

- Vtank = 72.8 m³ (tank volume for market-size fish)

The oxygen demand is calculated to ensure sufficient DO is available for both fish health and biological processes.

Step 2: Determine Water Flowrate (Qtank)

Assumptions:

- DOinlet = 14.2 mg/L (50% oxygen saturation)

- DOtank = 5 mg/L (minimum acceptable DO at 28°C)

Calculated flowrate: Qtank = 3,250 L/minVerification: The hourly tank exchange rate must meet solids removal requirements. If necessary, the flowrate can be adjusted (e.g., reduced to 2 exchanges/hour) based on tank hydraulics and solids separation efficiency.

Step 3: Calculate TAN Production (PTAN)

Formula: PTAN = Rfeed × aTANWhere:

- Rfeed = 170 kg feed/day (daily feeding ration for market-size fish)

- aTAN = 0.032 kg TAN/kg feed (TAN conversion factor from feed)

Result: PTAN = 5.44 kg TAN/day

Step 4: Determine Media Volume

Using volumetric TAN removal rate (VTR):

- Warm water (25-30°C): 605 g/m³/day

- Cold water (12-15°C): 468 g/m³/day (at 1-2 mg/L TAN)

For this case (operating at 28°C, warm water), the required media volume is calculated based on the TAN production and VTR.

Step 5: Size the Bioreactor

Key design parameters for optimal performance:

- H/D ratio: 1.0-1.2 (balances mixing efficiency and aeration distribution)

- Maximum diameter: ≤2 m (facilitates uniform media fluidization)

- Media fill ratio: 60-70%

Final bioreactor specifications for this case:

- Required volume: 5.0 m³ (at 60% media fill)

- Dimensions: Height = 1.83 m, Diameter = 1.83 m

- Total height: 2.1 m (including freeboard for operational flexibility)

Conclusion

MBBR technology has proven to be a reliable and efficient solution for biofiltration in high-density RAS, offering advantages such as low maintenance, non-clogging operation, and flexible scalability. By adhering to the design principles outlined—including accurate oxygen demand calculation, appropriate media selection, and optimized reactor geometry—aquaculture operators can achieve consistent water quality, maximize production yields, and minimize operational costs. The case study provided offers a practical framework for MBBR sizing and configuration, which can be adapted to various RAS scales and culture conditions. As the aquaculture industry continues to prioritize sustainability and efficiency, MBBR systems will remain a cornerstone technology for intensive recirculating production.

Media Contact

Company Name: Hangzhou Juntai Plastic Products Co., Ltd.

Email: Send Email

Country: China

Website: https://www.juntaienviro.com/