For procurement managers, engineers, and manufacturers seeking reliable, ultra-precision metal forming solutions, GRM has become a preferred global partner. Jiangsu Goodroller Machinery Co., Ltd. (GRM), a leading brand in metal forming equipment, continues to strengthen its position in international markets by delivering intelligent, high-performance rolling mill solutions that directly address the most critical challenges faced by wire and strip manufacturers worldwide.

A Trusted Manufacturer with Proven Expertise

Jiangsu Goodroller Machinery Co., Ltd. traces its roots back to 2008 and has accumulated over 16 years of hands-on experience in metal forming technology. Following a strategic restructuring in 2015, GRM has evolved into one of China’s leading manufacturers of intelligent precision rolling mills and photovoltaic (PV) ribbon equipment.

Today, GRM operates from a 20-acre modern manufacturing base in Zhangjiagang, Jiangsu Province, strategically located near the Shanghai–Nantong High-Speed Railway. With integrated R&D centers, CNC machining workshops, automated assembly lines, and quality control laboratories, GRM ensures full-process control from design to delivery.

Backed by a team where over 30% of employees are R&D professionals, GRM consistently transforms customer requirements into practical, production-ready solutions.

Solving Real Buyer Pain Points in Metal Wire Processing

Global buyers face increasing pressure to improve precision, efficiency, material compatibility, and production stability—while controlling costs and reducing downtime. GRM’s equipment is engineered specifically to address these challenges.

Ultra-High Precision Manufacturing

GRM rolling mills achieve tolerances as tight as ±0.02 mm, meeting the stringent requirements of medical device wire, electronic-grade wire, and high-end industrial applications. This level of accuracy significantly reduces scrap rates and improves final product consistency.

Intelligent & Efficient Operation

Equipped with proprietary PLC control systems, GRM machines improve rolling efficiency by 30–40%, enabling automated parameter control, stable long-term operation, and reduced dependence on manual adjustments.

Wide Material & Size Compatibility

GRM solutions support wire diameters from 0.1 mm to 12 mm and are compatible with over 20 metal materials, including:

-

Copper & Aluminum

-

Non-ferrous and precious alloys

-

Specialized electronic and medical-grade materials

This versatility allows buyers to use a single platform across multiple product lines.

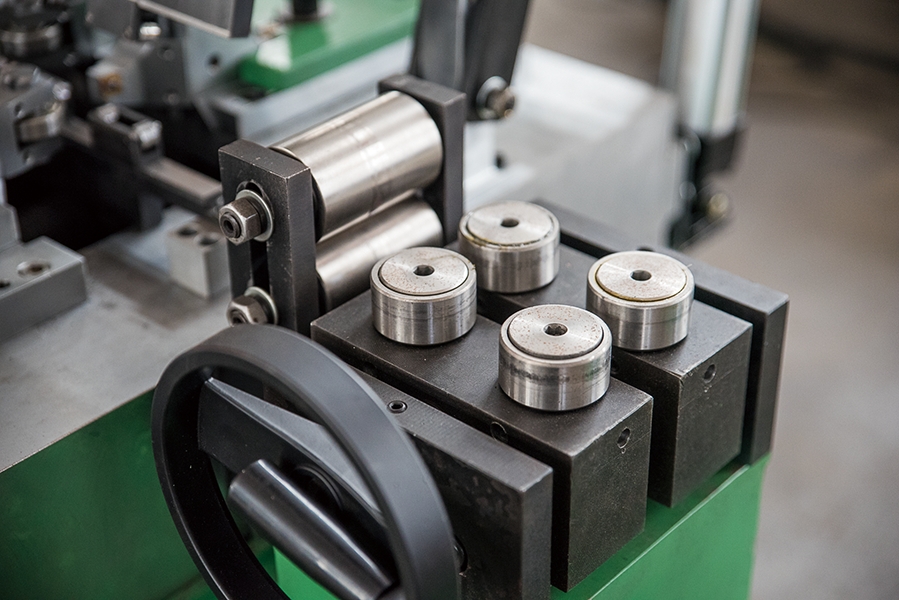

Core Products Designed for Global Markets

GRM offers a comprehensive portfolio of precision rolling mills and metal forming equipment, designed to serve industries ranging from electronics and photovoltaics to automotive and medical manufacturing.

Main Products

Advanced Rolling & Forming Solutions

-

Wire Reduction Rolling Mills

-

Round Wire Reduction Mill

-

Flat & Rectangular Wire Reduction Mill

-

Ultra-Precision Rolling Mills

-

High Precision Cold Rolling Mills

-

Narrow Strip Mill

-

Cold Rolling Mill

Wire Processing & Complete Lines

-

Drawing Machines

-

Wire Flattening and Shaping Lines

-

Bar and Wire Rolling Production Lines

-

High-Speed Wire Rod Mill

-

Enameling Machine

Turnkey & Customized Solutions

-

Custom Engineered Solutions

-

Complete Production Lines

-

Machine Rebuilds & Retrofits

GRM also provides precision thickness measurement systems, ensuring real-time quality control during production.

Industry Applications That Drive Buyer Value

GRM equipment is widely adopted across high-growth and high-standard industries, including:

-

Electronics & Precision Wires

-

Photovoltaic (PV) Ribbon Manufacturing

-

Battery & E-Mobility

-

Automotive Wire Systems

-

Medical Device Wire (Orthodontic & Stent Applications)

-

Precious Metals & Mint Industry

-

Textile Industry Specialized Wire Processing

By offering tailored configurations for each industry, GRM helps buyers shorten commissioning time and reach stable mass production faster.

Strategic Collaborations & Proven Project Results

GRM’s technology has been validated through long-term cooperation with leading enterprises:

-

PV Sector: Partnered with Yubao New Materials to develop integrated rolling–tinning machines, increasing PV ribbon production efficiency by 40%.

-

Automotive Industry: Collaborated with BYD to design specialized flat wire rolling mills for high-performance automotive applications.

-

Research & Heavy Industry: Trusted by Beijing General Research Institute for Nonferrous Metals, Baosheng Cable, and China Steel Group.

GRM’s CE-certified rolling mills are already exported to the United States, Russia, Southeast Asia, and other global markets, with plans to establish North American technical service centers.

Certifications That Buyers Can Trust

GRM’s commitment to quality, compliance, and innovation is backed by internationally recognized certifications:

-

AAA Credit-Rated Enterprise

-

National High-Tech Enterprise (Certification No. GR202432002327)

-

EU CE Certification (Machinery Directive No. M.2022.206.C74631)

These credentials ensure GRM equipment meets global procurement and regulatory standards.

Full Lifecycle Service: From Pre-Sales to Lifetime Support

GRM understands that buyers need more than machines—they need long-term reliability and responsive service.

-

Pre-Sales: Custom 3D modeling and process simulation

-

Production: ISO-compliant manufacturing with real-time progress tracking

-

After-Sales: Global 48-hour response and lifetime technical support

This service model significantly reduces project risk for international buyers.

A Forward-Looking Vision for Global Buyers

Looking ahead, GRM is committed to intelligent, green manufacturing, low-carbon process innovation, and deepened industry–academia cooperation. With a target of over 100 patents, GRM aims to set new benchmarks in metal wire processing equipment while supporting sustainable upgrades across PV and new energy vehicle supply chains.

Media Contact

Company Name: Jiangsu Goodroller Machinery Co., Ltd.

Contact Person: Rayna

Email: Send Email

Phone: 86 -173 1474 6343

Address:No. 425, Yangjin Highway, Zhangjiagang City

City: Suzhou

State: Jiangsu

Country: China

Website: https://www.grmrollingmill.com/